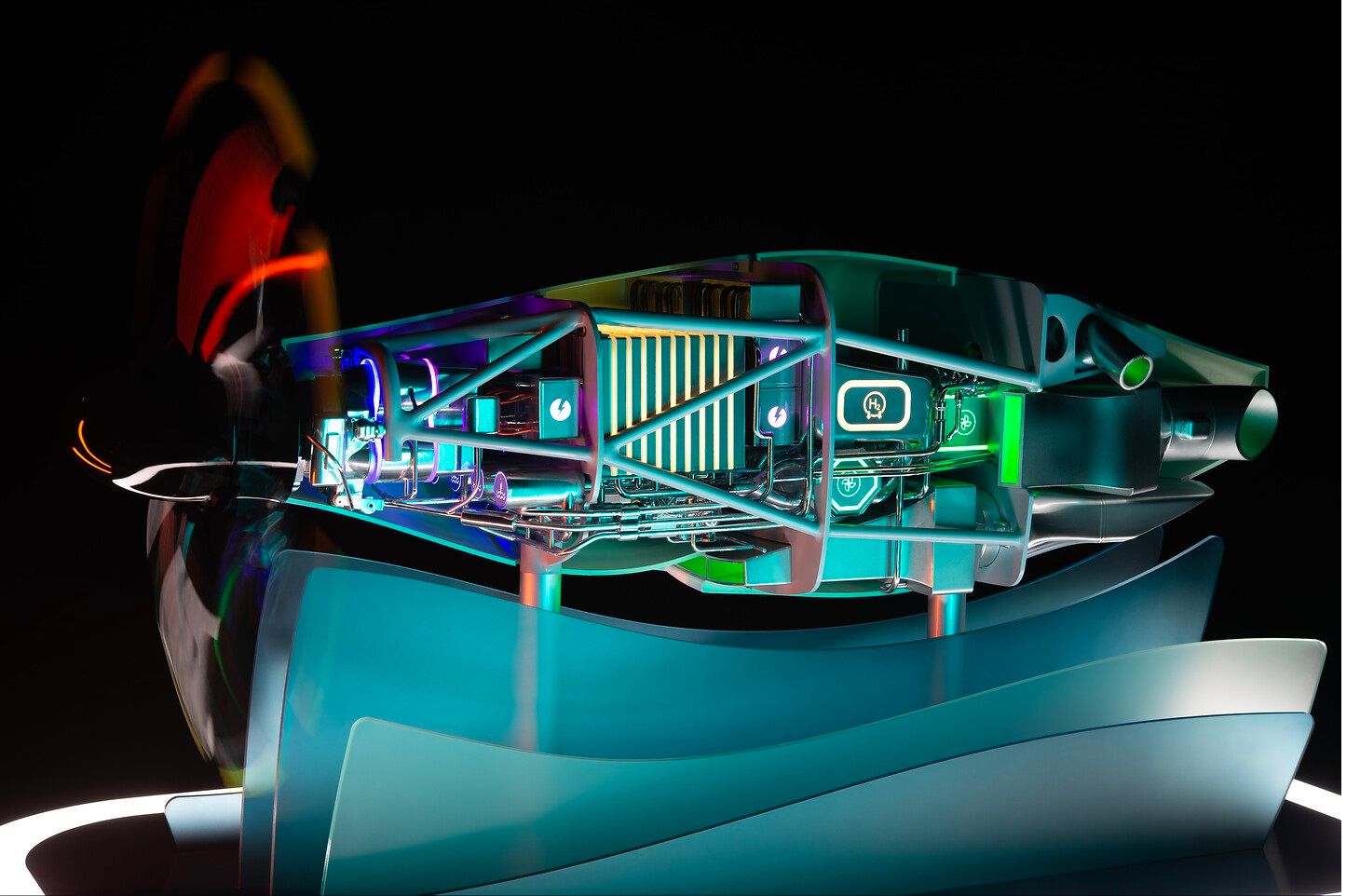

Hydrogen can be used as an alternative jet fuel to minimize carbon emissions on future aircraft. With three times more energy density than jet fuel, emissions from hydrogen-powered aircraft are significantly less detrimental to the environment. Hydrogen can be used to power aircraft in several ways.

Conventional gas turbine engines can be modified to use liquid hydrogen for combustion. Alternatively, electrical energy can be generated using hydrogen fuel cells, which are expected to be a more robust (and continuous) power source than batteries. A hybrid approach can be taken where the two hydrogen technologies (combustion and fuel cells) are combined.

Irrespective of the case, a continuous supply of hydrogen is required onboard the aircraft to obtain a substantial range of the aircraft. With the advantageous energy density of hydrogen, the volumetric density of hydrogen becomes its most significant challenge.

Hydrogen is significantly lighter than jet fuel and requires four times more volume on aircraft than jet fuel. Hence, the onboard storage of liquid hydrogen is challenging for aircraft manufacturers.

Cryogenic tanks

Cryogenic tanks are required to store liquid hydrogen at approximately -420 degrees F (-250 degrees C). Deep freeze temperatures require specialized materials, thicker walls, and sufficient isolation between stacks of cylinders.

For the past several years, Airbus has been working on building a zero-emission aircraft and bringing it to the market by 2035. With its European partners, Airbus is developing innovative cryogenic hydrogen storage tanks. Airbus has established two Zero Emission Development Centers (ZEDCs) in France and Germany to carry out the innovative tank design.

Airbus' ZEDC Centers

The center in Germany, with its close collaboration with Airbus Defense and Space technologies, provides hydrogen fuel expertise. The team is testing multiple designs to manage the gasification of hydrogen in the specialized cylinders.

The structure and metallurgy of the tank are designed in France. Rather than iterating on theoretical principles, both ZEDC teams have taken a practical approach to the problem. They manufacture multiple prototypes, test them under various conditions, and improve on the designs.

According to Airbus, France’s ZEDC team produced Airbus' first-ever cryogenic tank in just over a year. Airbus aims to test the working prototype(s) of the cryogenic tanks on its ZEROe test aircraft. The Head of Manufacturing of the ZEROe Aircraft and Head of Propulsion Industrial Architect, Chris Redfern, states,

"It's a real testament to the teamwork across our sites to see this first tank being manufactured so quickly. The agile methodology has delivered a great prototype and will help drive improvements in future iterations. We want to optimize the tank for greater efficiency and to reduce its environmental footprint further: after all, a zero-emission aircraft needs to be as close to zero emission as possible throughout its whole life cycle."

Airbus engineers are designing and testing cryogenic hydrogen cylinders on computational software in Toulouse. Results from the structural and flow analysis are shared with the ZEDC teams to review and make manufacturing improvements. Before beginning hydrogen tests, Airbus aims to test the first designed tank with nitrogen.

What do you think about the Airbus’ first-ever cryogenic hydrogen tank? Tell us in the comments section.