Airbus has revealed today that it has been selected by the European Commission to study the manufacture of antennas and satellites in space. Through the Horizon 2020 Program, Airbus will lead the PERASPERA In-Orbit Demonstration, or PERIOD project, focusing on building spacecraft while orbiting the Earth.

An in-orbit satellite factory

Airbus has been awarded a €3 million ($3.6 million) contract to study a revolutionary concept in space technology. The European manufacturer will work on the PERASPERA In-Orbit Demonstration project, coined ‘PERIOD’ for ease of explanation.

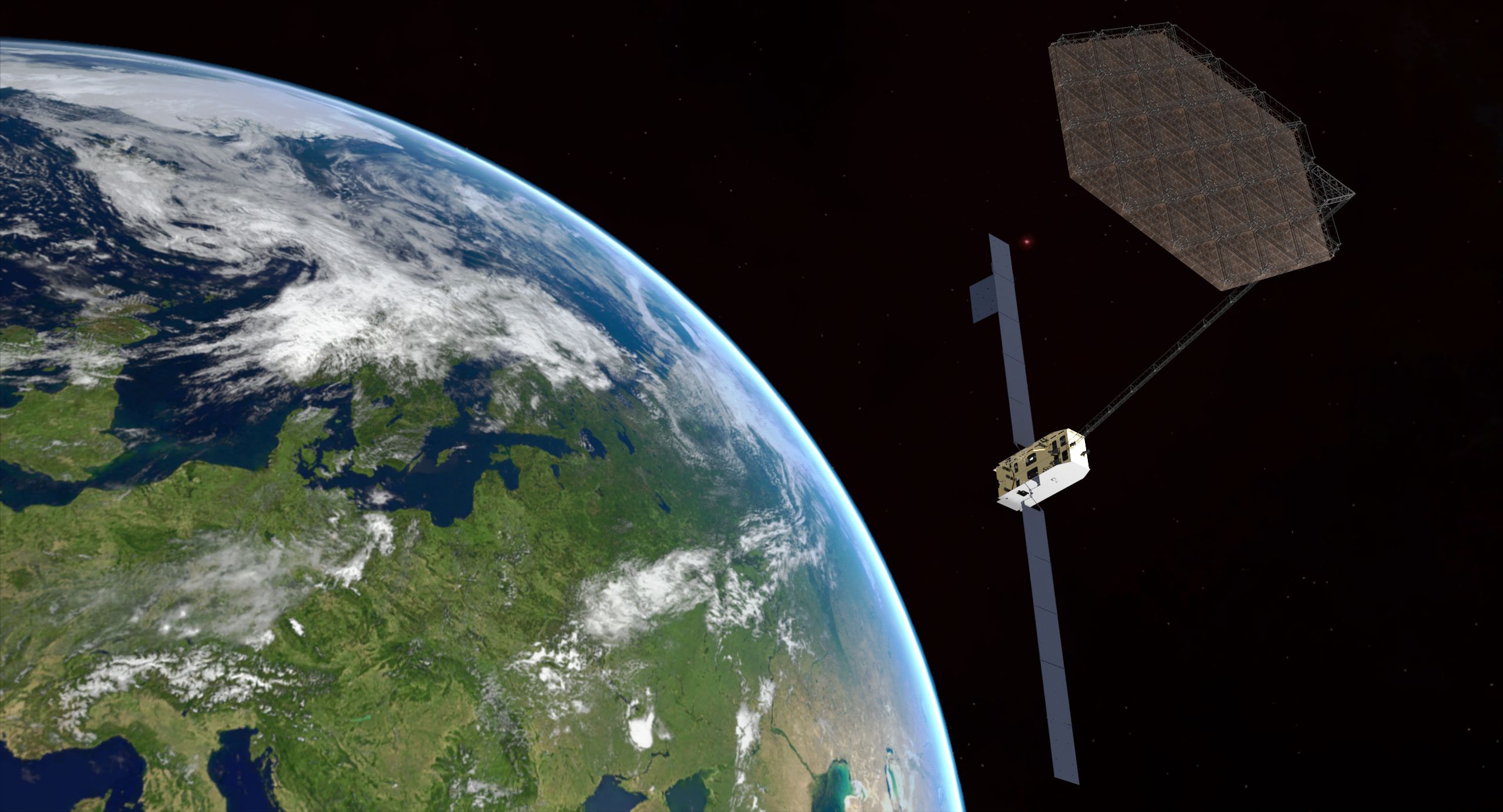

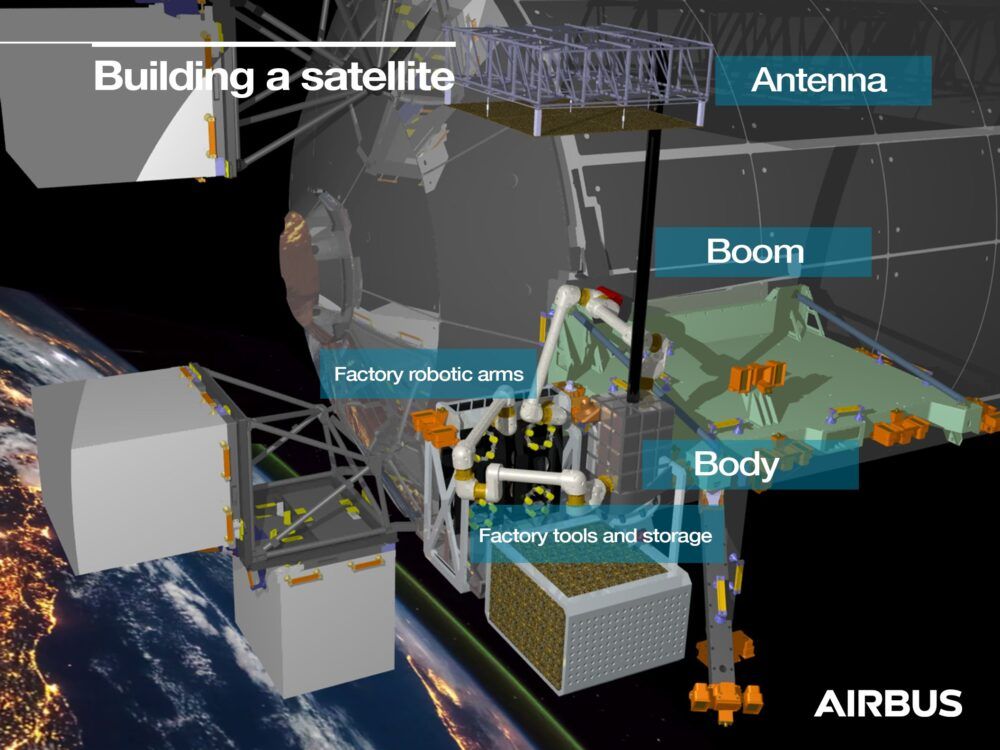

This initial contract will last for two years and will see Airbus developing a demonstrator in orbit to assemble and manufacture satellites. This ‘orbital factory’ will also seek to pioneer the construction of other spacecraft components, including antenna reflectors. It’s an ambitious and groundbreaking project, but Airbus believes it is the right partner to bring it to life.

Silvio Sandrone, head of Space Exploration future projects at Airbus, commented on the project saying,

“Airbus has been working on in-orbit manufacturing technologies for more than a decade and the PERIOD programme will help Europe move its combined technological know-how to the next level. Future large-scale space systems can only be manufactured and assembled in orbit, so it’s crucial that Europe is at the forefront of this key capability.”

Building satellites and other spacecraft on the ground has one key disadvantage – getting them into space. Launching a single satellite into space can cost anywhere between $10 million and $400 million, depending on the vehicle used and the weight of the payload being lifted. As an example, the Ariane 5 rocket used to launch payloads for Inmarsat's GX network costs around $165 million per launch.

It’s a problem that many have tried to solve, including Virgin Orbit with its Boeing 747 satellite launcher vehicle. But if the structures could be built in space in the first place, it would remove all the challenges of getting them airborne and would allow for larger, more advanced technologies to be developed.

How will Airbus build a space factory?

At this stage, this program is just about exploring the potential for an orbital satellite factory. It’s something of a precursor to making in-orbit manufacturing a reality. Nevertheless, it’s a key goal in the race to bring new technologies to space, and could lead on to much bigger and better things.

Airbus Defense and Space in Bremen is leading a team of seven European innovators to initiate the project. These include specialists in fields such as robotic operation, virtual reality, and in-space assembly. Partners include DFKI, EASN-TIS, GMV, GMV-SKY, ISISPACE, SENER Aeroespacial and Space Applications Services.

PERIOD aims to validate the capabilities to manufacture in space, as well as quantifying the advantages of investing in such a facility. The project hopes to stimulate more research into the sector, and to lead to jobs and growth in cutting-edge future technology.

Airbus is already working on a number of other in-space research activities, one of which includes the world’s first-ever metal 3D printer designed to be used in space. Metal3D will be deployed into orbit next year to demonstrate robotic and AI based in-space assembly.

This article is brought to you by Simple Flying Connectivity, a new category on Simple Flying dedicated to inflight connectivity. Click here to read all of our inflight connectivity content.