Reducing weight on aircraft is a top priority for environmentally conscious airlines, but as seats get smaller and lighter, is passenger comfort paying the price? Slovenian company Vanema has a solution that ticks all the boxes, saving weight and adding comfort all at the same time. It’s called the Octospring.

Getting weight off the plane

Airlines are doing all they can to make their aircraft lighter. After all, a lighter aircraft burns less fuel, and therefore pollutes less too. It also costs less to operate, which is a saving airlines can (hopefully) pass on to their customers through cheaper fares.

Weight saving comes in many shapes and sizes, from removing inflight magazines and duty-free carts to the less popular seatback screen removal. Seat design companies are working hard to create comfortable aircraft seats that weigh less than their predecessors, but what about the seat cushions themselves?

Slovenian company Vanema believes it has found a way to make seat cushions not only much lighter than they are right now, but also much more comfortable for passengers. In a world where low-cost airlines have us practically sitting on lightly padded plywood for our flights, that has to be good news for our bottoms.

Octaspring

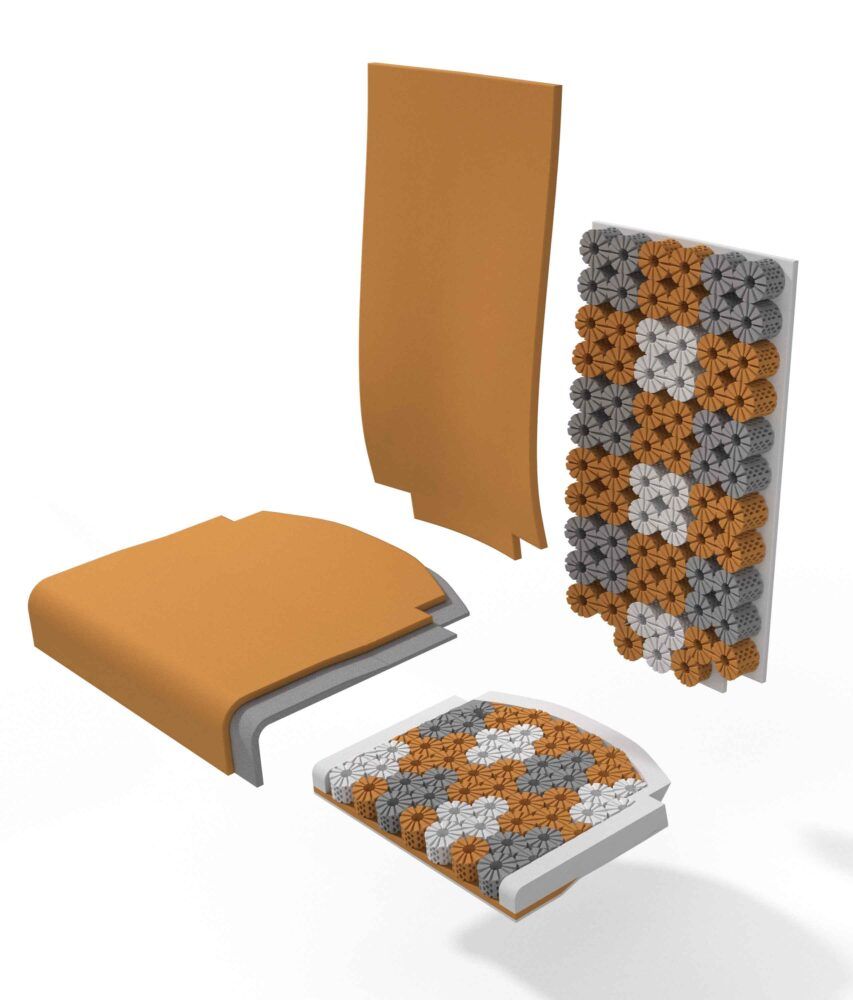

Vanema’s product is called Octaspring, and is a rather simple soliton to a very complex problem. Using a honeycomb-style arrangement of foam ‘springs’, the product delivers much greater passenger comfort than a static foam cushion. Because the springs are little honeycombs in themselves, they use around 50% less material in production than a solid foam pad would, making them kinder on resources too.

In terms of weight saving, the patented technology offers around a 30% weight reduction compared to solid seat pad technology. In economy class, this means around a 150g weight saving per seat cushion. In business class, it’s up to 800g of weight reduction per seat. The company also has solutions for first class seating, crew rest area mattresses and pilots’ seats too.

Vanema is working in partnership with Airbus, STELIA Aerospace and SAGROUP to bring the Octaspring to the aircraft cabin. The patented technology has already passed aviation-grade certifications, including fire retardancy and durability, so it really could be coming to a seat near you soon.

But is it really comfortable?

While our bodies will be the real judge of this, with no opportunity to try out the Octaspring seat cushion right now, we’ll have to base an assessment on what we know about the product. From the outset, things look good for this seating innovation.

The Octaspring seat cushion isn’t’ just a bunch of identical foam springs. Rather, Vanema has worked to develop ergonomic support in the seat, changing the firmness of the springs based on how people sit in the seat. Placement of the firmness zones can be tailored to the type of aircraft or length of route, and to suit seats that convert into beds or that recline less or more.

As the passenger moves, the springs work to distribute their weight evenly, alleviating pressure on the parts of the body in contact with the seat. Because the springs are ventilated, they naturally allow air to pass through. As the passenger moves around, hot and humid air is expelled from the cushion and fresh air is drawn back in. The company says this results in a seat capable of keeping you three degrees cooler.

Vanema says that the longer you sit in an Octaspring seat, the more comfortable it gets. We’ll have to wait for it to arrive on an aircraft to substantiate that claim, but on paper, at least, it looks like a winning solution. Good for the planet, good for the airline and good for our bottoms.