Boeing's largest twin-engine aircraft, the 777X, is scheduled to rollout next month. The aircraft will feature composite wings with folding wingtips and the new GE Aviation GE9X engine. According to an announcement by Boeing, both GE9X engines have recently been installed on the first flight test aircraft at Boeing's Everett assembly plant.

The GE9X Engine

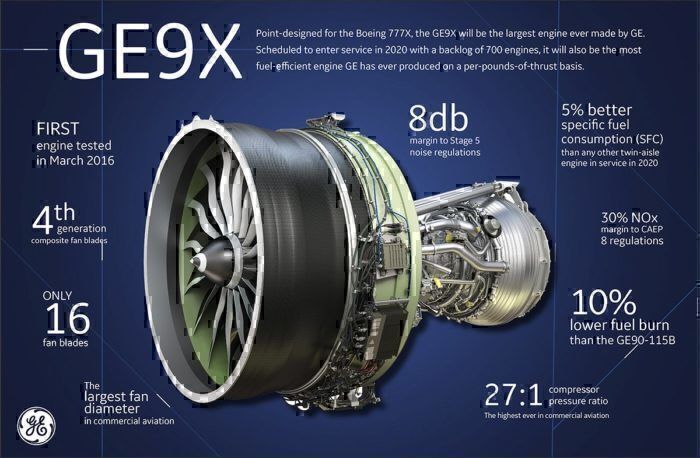

Let's take a closer look at the record-breaking GE9X engine. First of all, the GE9X engine is the largest turbofan engine in the world. The engine is about the same size as the fuselage of a Boeing 737. It is housed in a 14.5 foot nacelle, and its composite fan is more than 11 feet in diameter. Its blades and fuel nozzles are 3D printed, because 3D printing allows GE to produce more complex and efficient shapes.

According to GE Aviation, the GE9X is the most fuel-efficient and quietest jet engine ever produced by GE (on a per-pounds-of-thrust basis). It also has the lowest NOx emissions of any GE engine (on a per-pounds-of-thrust basis).

The GE9X engine is assembled in Durham, NC and Peebles, OH and is made of parts from the United States, Japan and Europe. It goes through extensive ground testing at GE's facilities in Peebles, OH.

GE9X vs. GE90 Engine

The GE9X engine might be the largest jet engine in the world, but it is not the most powerful. As a matter of fact, its predecessor, the GE90, is still the world's most powerful engine. The GE9X engine generates 105,000 pounds of thrust, while in 2002 a GE90-115B jet engine produced as much as 127,900 pounds of thrust setting the world record. Nonetheless, due to its aerodynamic efficiency and its larger 118-foot wing, the 777X will require less thrust than the GE90 powered Boeing 777.

[ege_cards_related id="30"]

Whereas the GE90 has 22 fan blades, the GE9X engine only has 16 decreasing weight and increasing efficiency. Furthermore, the GE9X engine features higher bypass and compression ratios and is expected to improve fuel efficiency by 10% over the GE90. The high pressure ratio of 27:1 (vs. 19:1 for the GE90) increases the temperature of the air by about 100 degrees Fahrenheit. While this increase in temperature leads to an increase in efficiency and a decrease in fuel burn, it is also tough on the engine and its components. As a result, GE used Ceramic Matrix Composite materials for parts installed in the combustor and turbine, because they have a greater heat resistance than the materials used in engines in the past.

Test Flight

The GE9X was flight tested for the first time in March of last year. At this time, a GE9X engine was mounted to a specially designed pylon on a Boeing 747 replacing one of its engines. This first test flight over the Mojave Desert went very well.

However, its first test flight on the Boeing 777X is coming closer. It is scheduled to take place in the second quarter of this year. If all the test flights go well, Emirates is set to launch operations of the 777X in mid-2020.

[ege_cards_related id="20"]

What do you think of the GE9X engine?