Despite a few recent wobbles, Boeing is one of the most iconic American companies and a globally recognized brand on par with the likes of Coca-Cola, Amazon, and Apple. While the parts that make up its aircraft may come from many places across the world, all of Boeing's final assembly lines (FAL) are based in the US, with a bonus completion and delivery center for the 737 in China. Let's take a closer look at what goes on where.

About half a million parts to make a single-aisle, three million for a Triple Seven

The making of an aircraft is no mean feat. A Boeing 737 NG narrowbody consists of approximately 500,000 parts. Meanwhile, a Boeing 777 is made up of about three million different pieces. Of course, not all of them are made in the same place or by the same suppliers, each providing its own specialty and expertise.

For example, wingtips for the Dreamliner are built in Buzan in South Korea, the landing gear for the same aircraft in Gloucester in the UK, and its horizontal stabilizer in Foggia, Italy. Meanwhile, some of Boeing's main subcontractors in the US include Spirit AeroSystems in Wichita, Kansas; Honeywell in Charlotte, North Carolina; Triumph Group in Berwyn, Pennsylvania. The US is also home to its engine suppliers - General Electric and Pratt & Whitney - while Rolls-Royce is based in the UK.

Accounting for the geographical location where all the millions of parts are made would, as you can imagine, require a very long list. However, let's take a look at where they are put together, and the sum of all those parts becomes the mechanical engineering marvels that are Boeing's commercial aircraft.

Everett, built to house the Queen of the Skies

Boeing's major production facilities are located at three different locations in the US. The Everett and Renton facilities are both situated in Washington State, whereas the third plant is located in Charleston, South Carolina.

Boeing's facility in Everett, Washington, opened the doors to its major assembly buildings for the first time on May 1, 1967. The planemaker built the plant especially to house the production of the 747 jumbojet, and the first specimen rolled out 16 months after the first working day.

The team working on the first 747-100 reportedly had to face several challenges as they were completing the aircraft while the factory was being built. Anecdotally, they even chased off a bear or two. For their troubles, they were dubbed with the honorary title - 'The Incredibles'.

Today, Everett's main assembly building has grown to encompass 472 million cubic feet of space over 98.3 acres. That is about five and a half times larger than the Great Pyramid of Giza and earns it the title of the largest building in the world by volume. Boeing is currently assembling the last ever Queen of the Skies, a 747-8F to be delivered to Atlas Air.

Meanwhile, as the production of the Queen winds down after more than 50 years, the Everett facility will be far from idle. It also houses the assembly lines of Boeing's newer dual-aisle aircraft - the 767, the 777, and, up until March last year, the 787 Dreamliner.

The mammoth aircraft construction site is served by Paine Field Airport, one of the reasons Boeing chose the location in the first place. Furthermore, in 2006, it was awarded the Guinness World Record for "largest digital graphic."

For an in-depth photo tour of Boeing's construction facilities, check out this story!

Dreamliner consolidation in SC

The decision to shift all Dreamliner production from Everett to North Charleston came at the beginning of October 2020 in a move to increase efficiency. Let's take a small geographical hop across the continent to check in with what else goes on at Boeing's South Carolina location before heading back to Washington State and Renton.

Boeing first selected North Charleston as the location for the final assembly line for the 787 in 2009. The very first Dreamliner rolled out through the doors on April 27, 2012, took its first flight a little under a month later, and was delivered to Air India on October 5 the same year - four years behind the initial schedule.

Boeing's South Carolina plant was the company's first to function on 100% renewable energy. Up to 20% of the energy it consumes comes from solar panels situated on top of the Dreamliner FAL building, equalling about 20 acres (or almost 20 American football fields).

Stay informed: Sign up for our daily and weekly aviation news digests!

The Renton jet age

Boomeranging back across the continent, we land back in Washington state and Boeing's 737 construction facilities in Renton. The plant has a long history, which includes being the home of Boeing's first turbine engine aircraft, the 707. The first prototype, designated the Boeing 367-80, rolled out from the factory in May 1954.

Renton also served as the FAL for the Boeing 727 trijet between 1963 and 1984. To accommodate newcomer 737, the manufacturer built a new assembly line in 1966. All of the models of the 737 family have passed through it - with over 10,000 aircraft built. Renton also housed the production of the 757 between 1981 and 2004.

Today, production revolves around the 737 MAX aircraft. Following the lengthy grounding of the aircraft after two lethal and tragic crashes and as a result of the downturn caused by the pandemic, Boeing lost some orders for the jet. However, interest in the aircraft and its efficiency has since resurged, and it has now amassed a total of orders for 6,479 jets, according to the manufacturer's own statistics from August 31, 2022. It still has to deliver 4,174 of them.

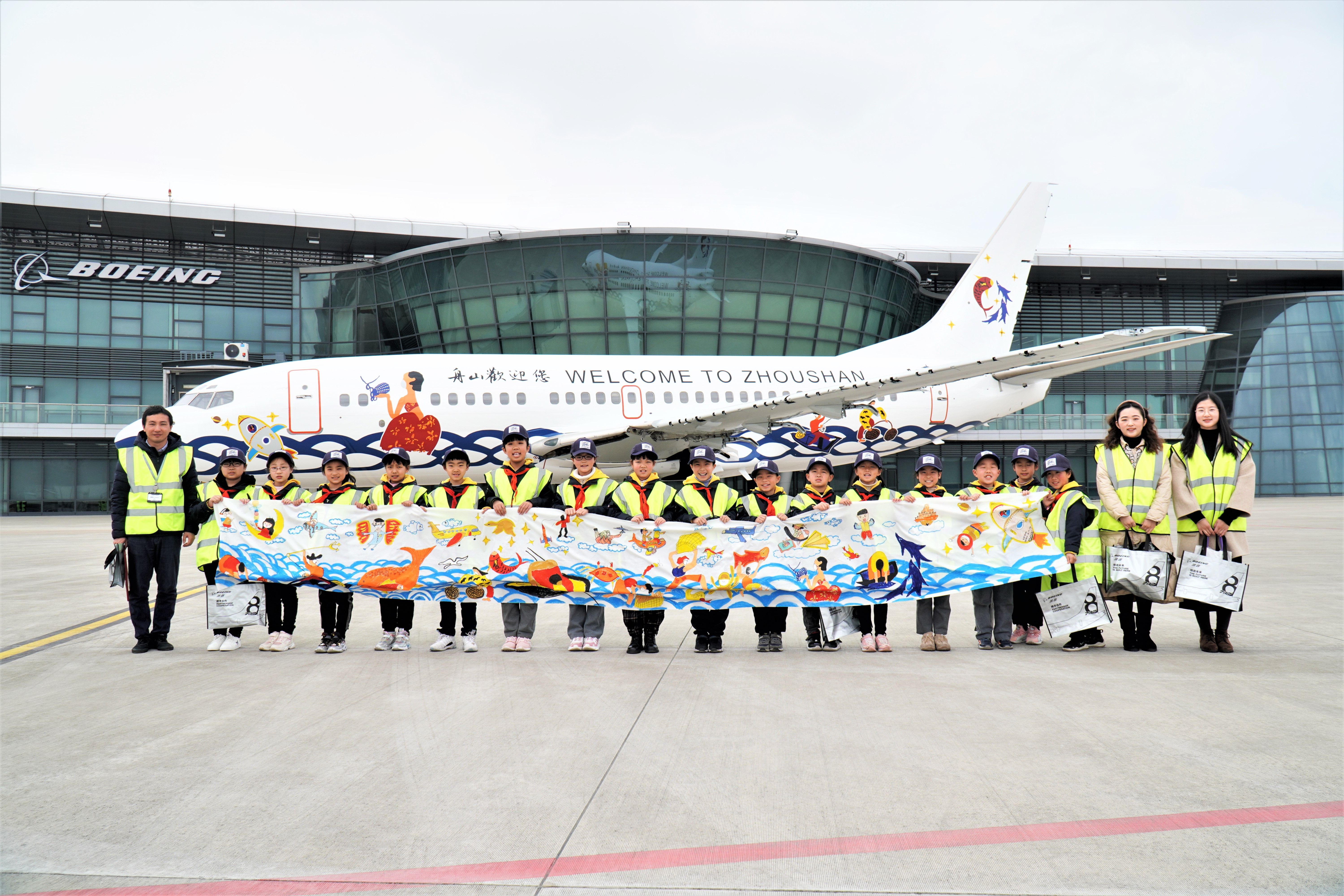

Honorary mention of Zhousan

In 2018, Boeing opened a completion and delivery center for the 737 in Zhousan to better serve its Chinese narrowbody customers, which in 2017 represented 26% of its global aircraft deliveries. The Zhousan facility delivered its first plane, a 737 MAX 8, in December, to Air China the same year. While deliveries were halted during the type's grounding, Boeing China's President said as late as August 2022 that the facility was ready to resume deliveries of the MAX in the country.

Have you ever visited any of Boeing's main factories? What was it like? Leave a comment below and share your stories with us.

-A6-ECK-(2).jpeg)