Thanks to additive manufacturing techniques, General Electric combined more than 300 engine parts into only seven on the GE9X engine. Additive manufacturing techniques use Computer Aided Design (CAD) software or three-dimensional object scanners to direct machines to deposit specialized material, layer upon layer, in precise geometric shapes.

Design information from the CAD software guides the path of a nozzle or print head as it deposits material into a specific form. Each successive layer bonds to the preceding layer of melted or partially melted material. The process repeats until the entire part is created.

The loose or un-fused material is removed during post-processing and recycled for the next part. The additive manufacturing process differs from conventional processes, where materials are machined, milled, or carved to obtain a desired form.

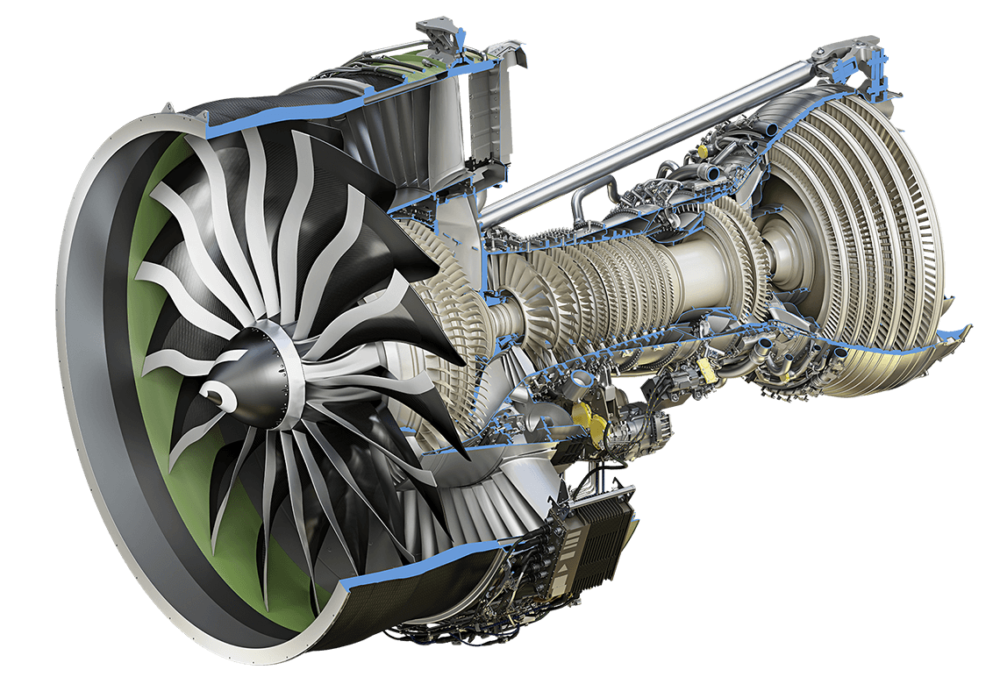

General Electric GE9X engine

The GE9X is the largest and most powerful aircraft engine in the commercial aviation market. The high-bypass turbofan, derived from the GE90, features a massive fan, advanced materials, and higher bypass and compression ratios. With the maximum capability of producing 134,300 lbf (pound-force) of thrust, it is 5% more potent than its predecessor.

Despite its capability, the engine is currently rated at 110,000 lbf of takeoff thrust. Advanced materials and processes make the engine more efficient, quieter, and with fewer emissions. General Electric's GE9X is explicitly designed for Boeing's latest member of the 777 family, the Boeing 777X.

Reducing the number of parts on the GE9X engine

The heart of the turbofan engine is its high-pressure compressor, also known as the core. The compressor ensures incoming air gets compressed to an optimum pressure ideal for combustion. It comprises a series of compressor stages (rotary blades and stationary vanes) that gradually compress the air.

In a conventional design, compressor blades on each stage are individually attached (with spacers, retainers, and bolts) to the disk or drum. A disk (or bladed disk) is made of rotor disks and blades; each rotating stage may consist of hundreds of individual parts.

The first five stages of the GE9X engine's high-pressure compressor are considered blisks (combined bladed disks). A blisk consists of a single part connecting the disk and rotating blades through additive manufacturing, integral casting, or simply welding individual blades to a rotor disk.

Eliminating the need to attach blades to the disk decreases the number of components in the compressor. Blisks significantly minimize drag and increase the overall efficiency of the GE9X engine by up to 8%. Moreover, the design eliminates the source of crack initiation and propagation in the blades' dovetail slots (attachments).

Blisks undergo rigorous harmonic vibration testing and dynamic balancing to an extremely high standard. This is because the damping of the dovetail attachment is not present in blisks. A significant disadvantage of blisks is that any damage to the blades beyond minor dents requires complete engine removal so that the blisk may be repaired or replaced.

Want answers to more key questions in aviation? Check out the rest of our guides here.

Apart from additive manufacturing techniques, using lightweight ultra-strength materials has also helped GE reduce the number of parts. For example, by using advanced materials, GE has manufactured thinner, lighter, and more efficient fan blades. As a comparison, the GE90 comprises 22 blades, the GEnx holds 18, and the largest of the three, the GE9X, has only 16 blades.

What are your thoughts on the additive manufacturing techniques used by GE on the GE9X engine? Tell us in the comments section.