In a concept that has unified the approach of engine Orginal Equipment Manufacturers (OEMs) and their partners toward sustainable programs in aviation, GKN Aerospace has entered into a joint technological development program with GE Aviation. The collaboration aims to develop the open-fan architecture for the CFM Revolutionary Innovation for Sustainable Engines (RISE) engine demonstrator program.

About the RISE program

CFM, a 50-50 joint venture of GE Aviation and Safran, launched the RISE program last year, intending to contribute to the aerospace industry's pursuit of net-zero emissions and flight. Building on four decades worth of investments to make engines cleaner, quieter, and still more efficient, the program accelerates the development of new propulsion technologies that draw the path for next-generation aircraft and enhance sustainability.

Matured technologies from the RISE Program will serve as the foundation for the next-generation CFM engine that could be available by the mid-2030, with the primary selling point of reducing fuel consumption and carbon emissions by more than 20% compared to today's most efficient engines. The next generation should also be compatible with alternative energy sources such as Sustainable Aviation Fuels (SAF) and hydrogen to further the sustainability efforts.

Simple Flying is at the Farnborough Airshow this week. For all the latest news from the show, click here!

Thinking outside the box

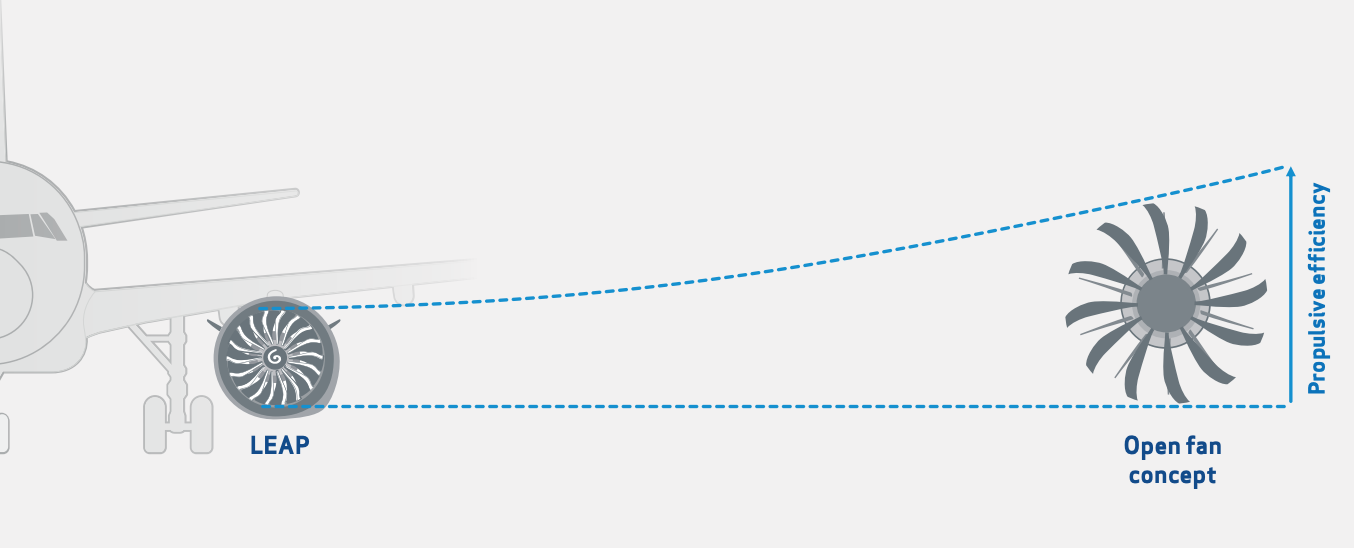

One of the most favored technological concepts from the RISE program is the idea of an open-fan engine meant to improve propulsive efficiency. Over the years, the need for increased propulsive efficiency has driven the growth of engine fan diameters. The GE90 is the current biggest engine for operating widebodies, and the CFM LEAP series is the biggest on narrowbodies. However, there still remains a limit to how big and wide engine fans can be in terms of aerodynamics, stability, and sustainability.

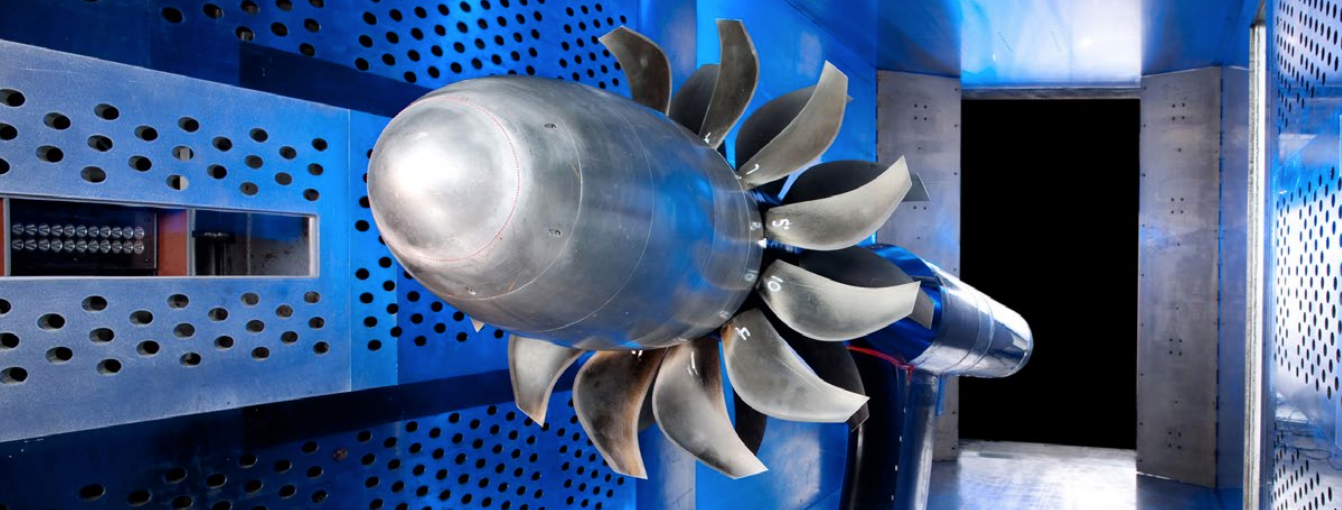

The open-fan concept is unlike any conventional jet engine design as it features an advanced 14-foot diameter fan in the front, with a rose of non-rotating variable-pitch stators behind it. Such a non-traditional concept is in line with the notion that the highest fuel efficiency involves propelling an enormous amount of air at the lowest exhaust velocity.

Although high bypass architectures can be seen in turboprops on slower flying and shorter-range regional aircraft today, the open-fan concept to be matured from the RISE Program is nothing like a turboprop engine. As a matter of fact, the developed idea will be able to fly at the same speed as a current single-aisle aircraft, at up to Mach 0.8, with a noise signature that will meet forecasted future regulations.

Lending an expert hand

For the development of the open-fan conceptual engines, CFM has established a full-scaled roadmap with more than 300 different components, modules, and full-engine builds to test and mature the technologies. And this is where GKN Aerospace steps in during the collaboration, as after it acquired Volvo Aero, it stands as one of the world's leading multi-technology tier 1 aerospace suppliers. The company's capabilities include developing, building, and supplying an expansive range of advanced aerospace components, systems, and technologies.

Then there's the company's Swedish arm, which has an excellent reputation as a design partner for aero-engines and specializes in cooled nozzle extensions and turbines. With its expertise, GKN Aerospace will be a fruitful partnership in the demonstrator program through the injection of its latest component designs, technologies, and production of hardware scaled to support the program's objectives and eventual validation plan.

Alexander Andersson, GKN Aerospace Senior Vice President of Programs, said:

“GE Aviation and GKN Aerospace have had a relationship for more than 40 years. Over the years, we have grown our responsibility on GE engines, and today we are in long-term partnerships with design authorities in several programs. The next step in this partnership is to ensure we continue investing in the right technologies and tailor our solutions to create the best value for our customers."

With GKN Aerospace onboard the program, the maturing of the technologies for the open-fan engine concept can move quicker, allowing the new engines to be on track to enter service in the mid-2030s. Flight tests of the engine are scheduled for the middle of this decade. Once everything is completed and given the green light, passengers could soon start seeing open-fan engines on their flight as aircraft manufacturers integrate them onto various airframes.