While other areas of aviation, such as enhanced passenger experiences and biometric systems, may also come to define the coming decades, the industry is facing two of its greatest transitions to date - decarbonization and digitalization. And the implementation of the latter will most certainly support the quest for the former.

We may have to wait a while for the major technological step changes that will (most likely) come in the form of electric and hydrogen propulsion. In the meantime, any incremental efficiency gains that can be had will mean crucial fuel savings and push the needle on CO2 emissions. Furthermore, gradual learning and implementation will help inform technological breakthroughs.

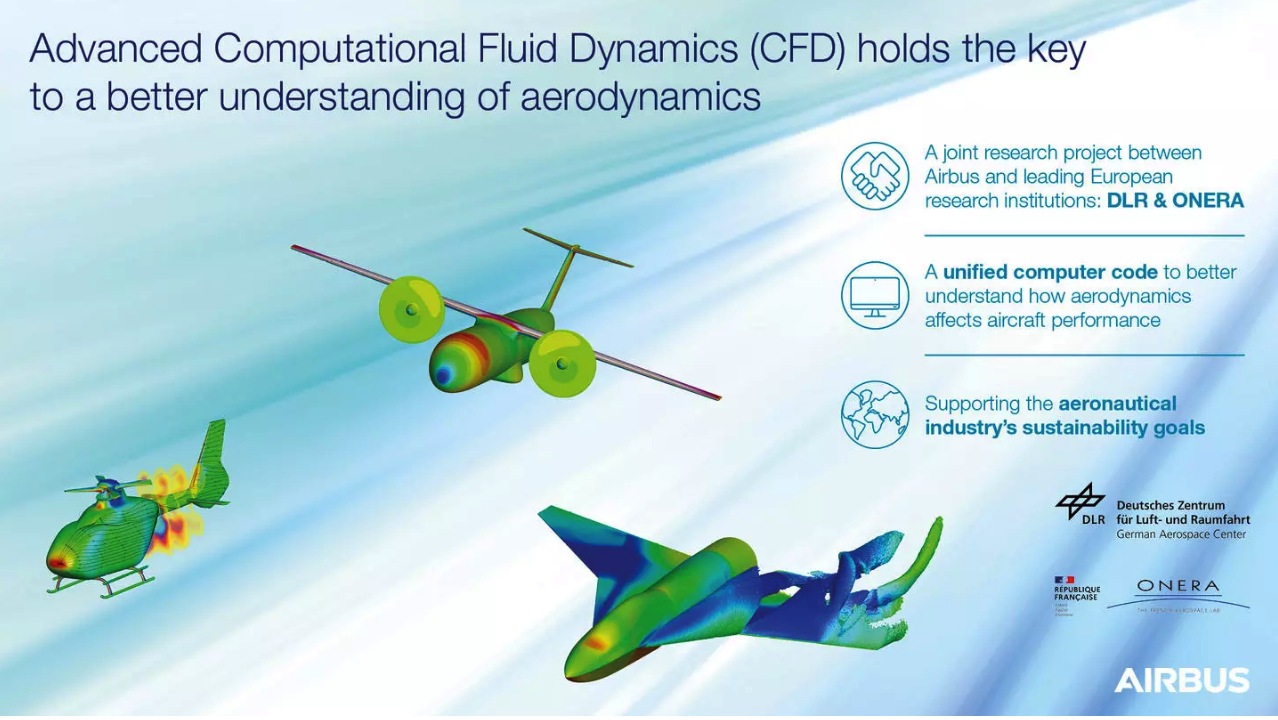

Understanding how air moves over complex shapes, such as aircraft and their wings, helps engineers reduce drag and maximize lift. In order to gain the best insight possible into how to design the most efficient aircraft of the future, engineers at European aerospace giant Airbus are utilizing what is known as computational fluid dynamics (CFD).

CFD simulates fluid flows and then produces quantitative predictions of the flow phenomena, utilizing a combination of mathematics, physics, and high-performance computer algorithms. Airbus is partnering with the German Aerospace Center (DLR) and the Office National d'Etudes et de Recherches Aérospatiales (ONERA) to explore how the approach can help inform aerodynamics and increase efficiency.

Airbus’ Head of Aerodynamics, Simon Galpin, explains the approach like this,

“I always say that CFD is where science meets art. It’s a beautiful thing, a kind of computerised wind tunnel."

'Industry-ready' flow predictions

Galpin further continued on the partnership with the German and French aerospace research centers, which was first established in 2017 and then renewed last year,

“It made sense to combine our efforts. We’re developing a new generation CFD code that is ‘industry-ready’ for flow prediction and equally applicable to aircraft, helicopters and space systems.”

The purpose of the renewed partnership is to expand the application to Airbus' current and future projects including hydrogen-focused ZEROe, hybrid-propulsion EcoPulse, and the Revolutionary Innovation for Sustainable Engines (RISE) program OpenFan concept in collaboration with CFM.

Get the latest aviation news straight to your inbox: Sign up for our newsletters today.

The trio of aerospace expert organizations says it is already using CFD to mature test cases that were previously thought unfeasible due to limited physical representation and computational capacity. This will then help inform wing and engine design in order to increase efficiency and support the transition to cleaner aviation.

Galpin explains,

“We better be extracting every gram of energy from every kilogram of alternative fuel, using the most efficient aircraft architecture. Using advanced CFD helps us shave off drag little by little.”

Attracting talent in tech

As many industries seek to decarbonize simultaneously, one of the main challenges for aerospace will be to attract talent across relevan digital technologies. Airbus believes that cutting-edge collaborations, such as this one with DLR and ONERA, will draw future engineers to its cause.

Pascal Larrieu, Airbus Computational Simulation Expert, commented,

“This project opens doors to a diverse, dynamic and Europe-wide research network. We’re convinced our work will help attract future aeronautics engineers to join us in meeting our decarbonisation ambition together.”

Want to learn more about sustainability in aviation?

Source: Airbus