Summary

- Jet engines consist of intake, compressor stage, combustor, and turbine stage. Air is compressed, fuel is introduced, and expansion creates thrust.

- N2 compressor must be rotated to start the engine. This can be achieved using electricity or an air starter motor.

- Startup malfunctions include hot starts (insufficient airflow) and hung starts (low RPM). A blowout cycle is necessary if a start fails to clear excess fuel. In-flight restarts rely on windmilling or assistance from other engines or APU.

Jet engines are complex and expensive machines that require safe handling, proper care, and routine maintenance. While aircraft engines may serve a similar purpose as an automobile machine - providing power, starting an engine is not as simple as turning on the car ignition. Pilots must perform a series of steps required to perform the jet engine start up process.

Pilots carry specialized checklists for engine startups. The engine uses air from one of the three primary sources for start up: an onboard Auxiliary Power Unit (APU), a Ground Power Unit (GPU) from the ramp, or cross bleed (air from another engine when functional). This article delves deeper into the general principle of jet engines, their functionality, and the steps required in performing engine start up.

The components of a jet engine that are involved in the startup

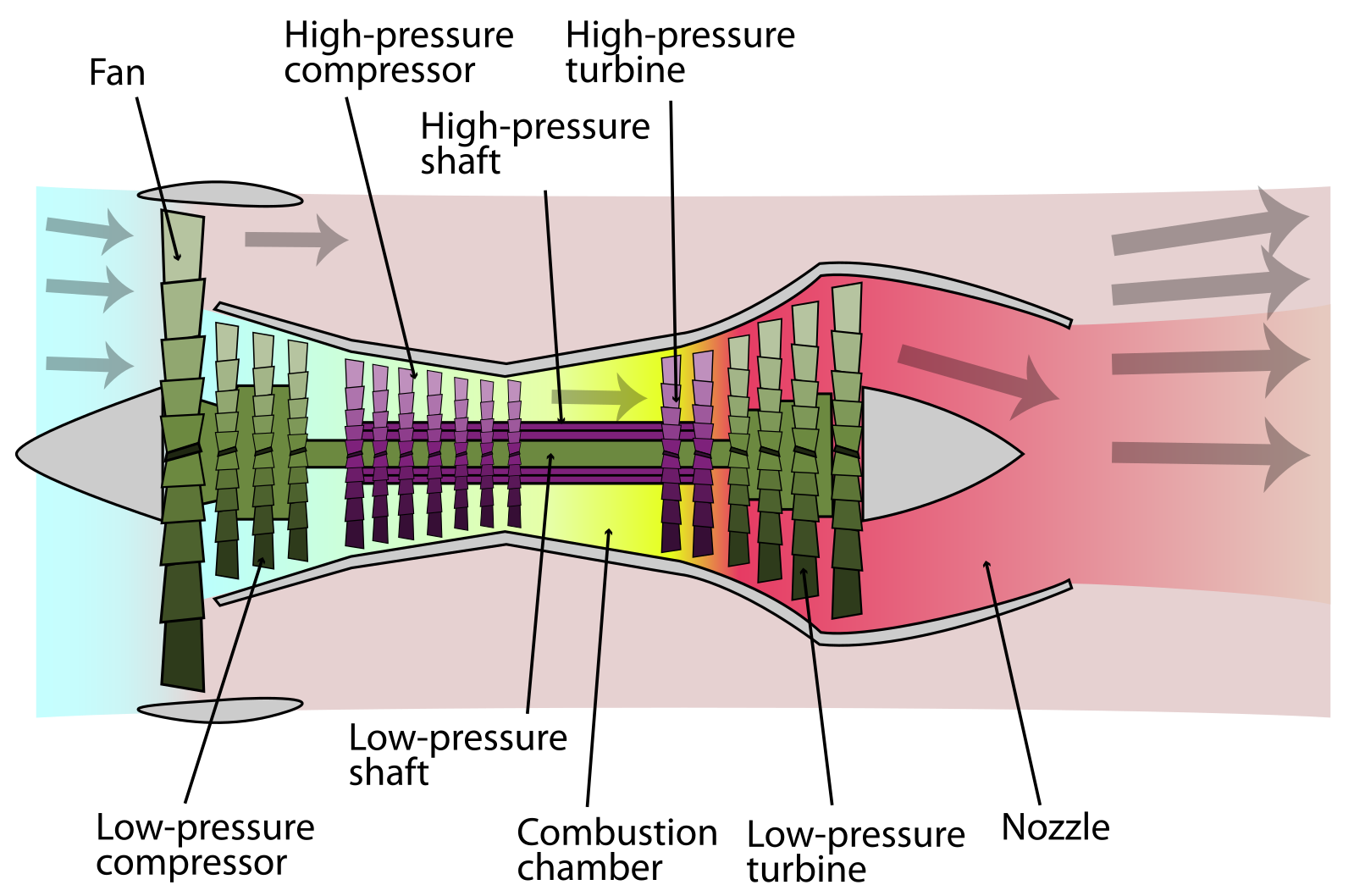

To summarize, a typical jet engine consists of an intake, a compressor stage, a combustor, and a turbine stage. It works very similarly to the engine in a car. Firstly, the air is drawn into the intake, which is then compressed. From the compressor stage, the air is passed into the combustion chamber, where fuel and ignition are introduced, which then burns the air.

This air is then passed into the turbines, where it is allowed to expand. This expansion increases the kinetic energy of the flow, and as it races out of the engine, an equal and opposite force is applied to the aircraft. This is called thrust.

To draw air for the startup, the compressor stage first needs to be turned at a certain speed. This is the first requirement to start a jet engine. In its most basic form, a high bypass ratio jet engine has two compressor stages. The low compressor stage is known as N1, and the high-pressure stage is known as N2. During the startup process, the N2 compressor is the one that needs to be rotated as most of the engine accessories (oil and hydraulic pumps, etc) are connected to this compressor.

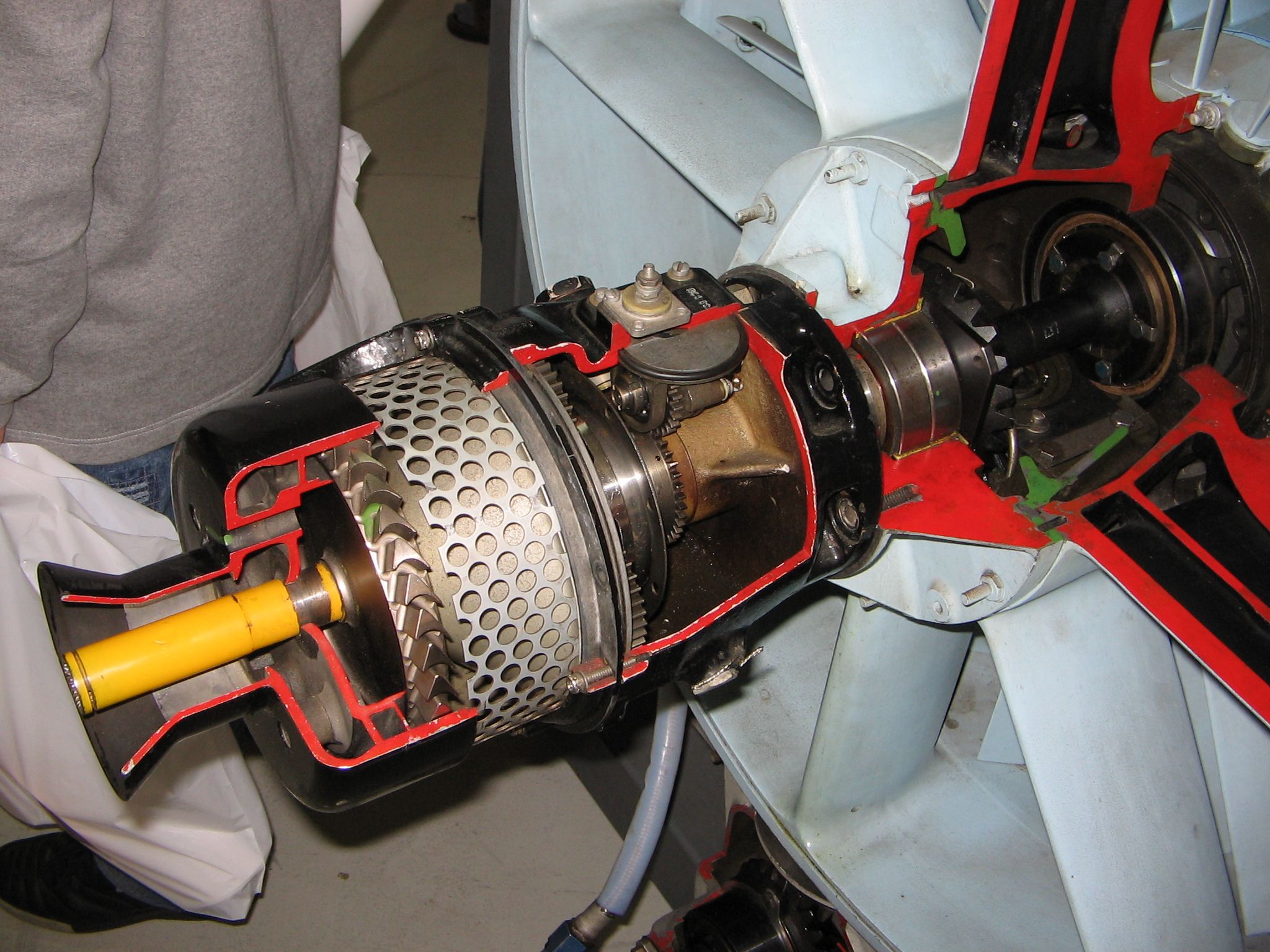

There are two methods by which the N2 compressor can be rotated. One is by using electricity. This method is mostly used to start smaller-sized jet engines like those found in turboprops. Here, one of the electrical generators of the engine acts like a starter motor. When it is energized, it turns, and as it is geared to the N2 compressor, this causes the N2 compressor to rotate.

The second method is used by larger jet engines. Here, a separate starter motor is used to turn the N2 compressor. The motor is called an air starter and is run purely by air. This air may be fed by an Auxiliary Power Unit (APU) or a Ground Start Unit.

The start procedure

As discussed above, the N2 compressor needs to be rotated to start a jet engine. To do so, air needs to be sent to the air starter motor. If the aircraft is equipped with an APU, this air, called bleed air, can be provided by the APU. During ground operations, the APU supplies air for the air conditioning units. However, during the startup, the air to these units is shut off so that the air is available for engine start.

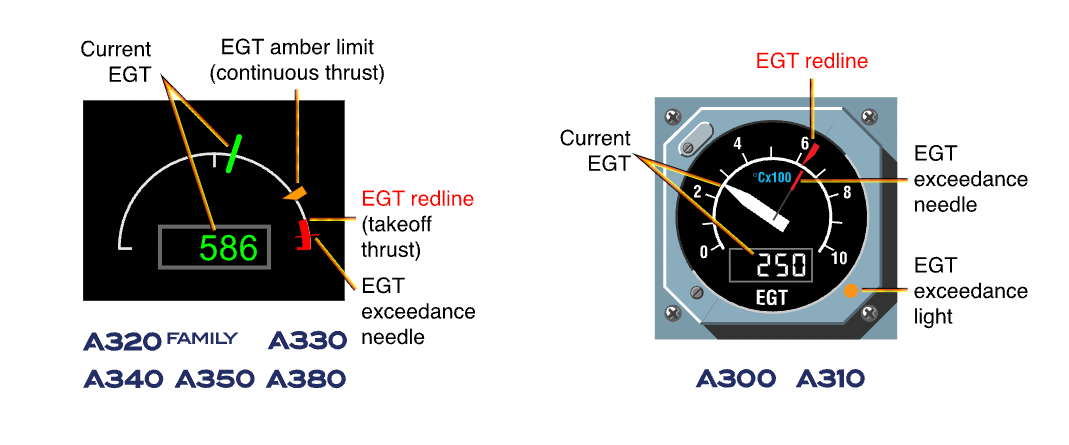

When the pilot engages the starter, the start valve opens, which allows the bleed air to be passed into the turbine of the starter motor. The starter motor then turns the N2. As the N2 builds up, the pilot monitors this from the cockpit instruments. At about 20% N2 rotation, fuel is introduced into the combustion chamber by the pilot using the fuel switches. The ignitors then fire up the fuel and air mixture, which causes the engine temperature to rise. In most jet engines, this temperature is sensed at the turbine stages or exhaust, and it is called Exhaust Gas Temperature (EGT).

As fuel is first introduced, there is a sharp rise in EGT due to the presence of excess fuel in the combustion chamber compared to air. Less air means less cooling. As the engine accelerates, more fuel is introduced, which progressively increases the EGT. At some point, the engine reaches a self-sustaining speed at which the engine can continue to accelerate without the assistance of the starter motor.

When this point is reached, the starter motor automatically de-clutches from the N2 compressor, and the igniters are switched off. The EGT then peaks at a value and then drops as the fuel and air become balanced in the combustion chamber. This ends the startup procedure.

The peak EGT is an important value. A high peak EGT shows possible engine degradation. This can also be due to a faulty engine starter motor. Either way, abnormally high peak EGTs during the start should be discussed with the maintenance before they become a bigger problem. The EGT itself shows the temperature of the turbines, and as they are sensitive to heat, there is a start EGT limit that must never be exceeded. If exceeded, the engine should be immediately shut down, and the aircraft should be handed over to maintenance.

When the APU is unserviceable or unavailable, a ground start unit can be hooked up to the aircraft. A long pipe from the start unit is connected to the adapter, which supplies the air from the unit to the engines. Pilots start one of their engines at the gate with the start unit when this method is used. Once the engine is running, it is disconnected from the aircraft. Then, the air from the fired-up engine can be diverted through a cross-bleed valve to start up the remaining engine(s). This type of starting is called a cross-bleed start.

For those engines started with an electrical generator or a motor, the same process applies, except there is no requirement to provide air for the startup. The Boeing 787 is the only large aircraft that uses electricity to start the engine. This requires a lot of power, and without an APU, two external ground power units are required to be connected to the aircraft for engine start.

Startup malfunctions

There are two main start malfunctions in a jet engine. One is called a hot start, and the other is called a Hung Start. In a hot start, as the fuel is introduced, the EGT rises as expected, but the temperature accelerates to the start EGT limit rapidly. If this happens, the pilots should immediately shut off the fuel and ignition. Delaying this can cause the EGT limit to be exceeded, and this may render the engine useless in a matter of seconds.

The reason for a hot start is simple. Insufficient airflow. A weak starter motor can cause this, the inability of the APU or the ground start unit to provide enough air, or a problem with the engine's electronic control unit. Starting the engine with a strong tailwind can also cause a hot start as the wind opposes the engine's rotation.

The engine compressor RPM fails to accelerate to the expected value or the self-sustaining speed in a hung start. It is ‘hung’ at an unacceptably low value, with the EGT being higher than what is expected for the low RPM. The pilot action in a hung start is to shut off the engine by closing off the fuel valves. A faulty starter motor mainly causes a hung start.

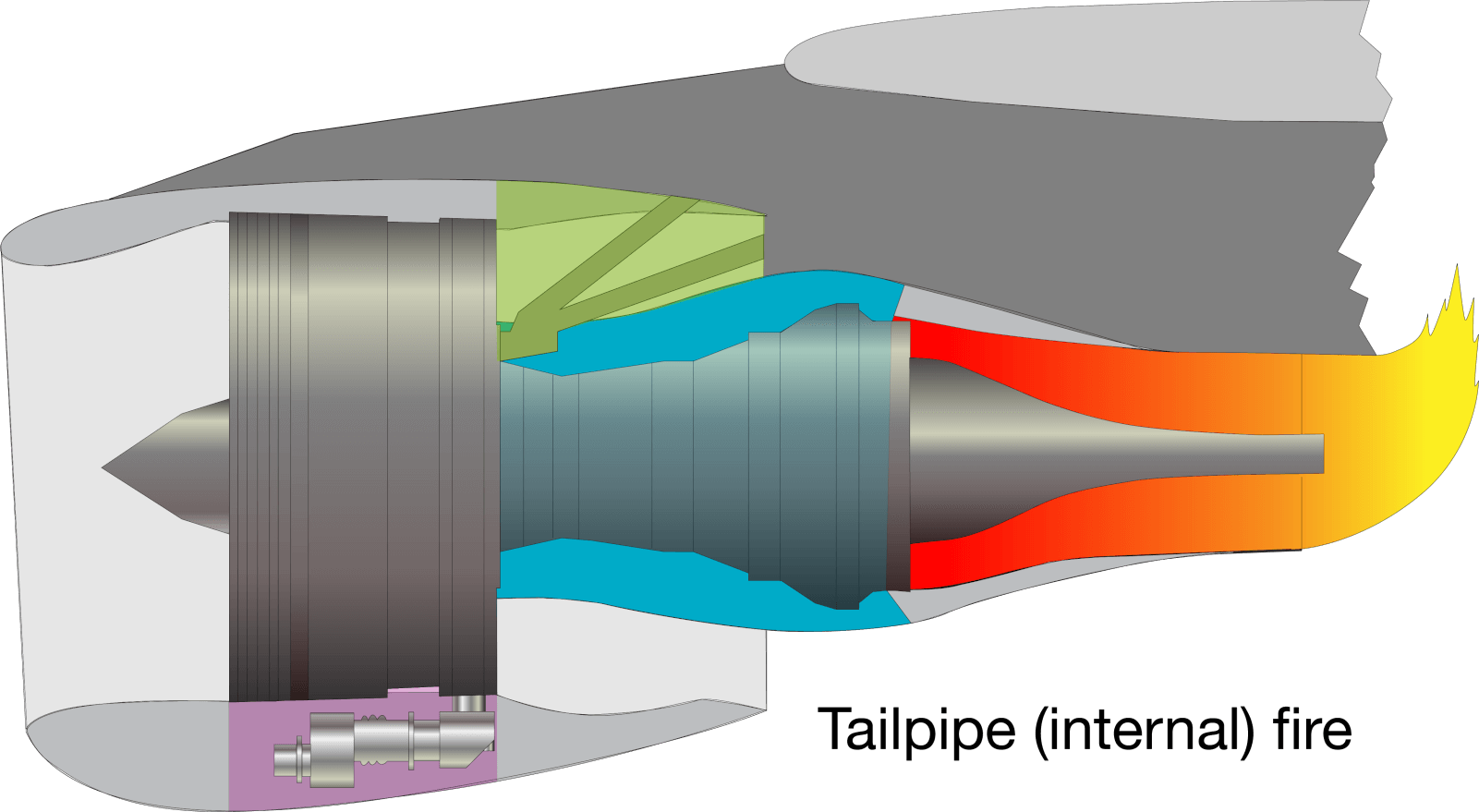

Any time an engine fails to start, before attempting a new start, the pilots must carry out something called a ‘blowout’ cycle. This is because, in most failed starts, unburnt fuel flooded in the combustion chamber. If a start is attempted with this fuel in the chamber, it can cause the flooded fuel to ignite, and flames can come out of the engine exhaust. This is called a tailpipe fire or torching.

Torching rarely damages engine components. However, it can damage the aircraft structures that are directly exposed to it, such as wing components and flaps. To carry out the blowout cycle, the pilots must turn off the ignition and simply run the starter motor without introducing fuel. This sends air through the combustion chamber and blows out excess fuel in it.

In-flight engine restarts

Jet engines are highly reliable. Even so, there is a chance of a failure up in the air. If an engine fails while flying, the pilots can perform an in-flight restart. The start of a jet engine in the air is similar to that of one on the ground. One significant difference is that when flying, the forward velocity of the aircraft turns the compressor automatically. This is called windmilling.

The faster the aircraft travels, the faster the rotation. Thus, the engine can be started in the air without the help of the starter motor if it is flown at a stable windmilling speed. Below this speed, air from the live engine or air from an operational APU may be required to turn the N2 compressor to an acceptable speed.

What are your thoughts on the steps involved in jet engine startup? Share your opinion in the comments section.