Reducing weight on board an aircraft is a high priority for any airline. Every additional ounce means more fuel burn, more expense, and more CO2 emissions. Airline seat manufacturers have been steadily reducing the weight of the cabin furniture over the years, but now there’s a new kid in town. AIRTEK is a business class seat solution that borrows from Formula One to create a lighter, more spacious, futuristic product. Here’s what you need to know.

Bringing Formula One technology to the aircraft cabin

A lighter plane costs less to fly, and helps airlines achieve their CO2 reduction goals too. We’ve seen some interesting approaches to driving down the carried weight of an aircraft. From removing inflight magazines to replacing seatback screens with a bring your own device policy, airlines are always in search of ways to trim the weight onboard.

However, seats remain one of the weightiest components of the aircraft cabin. While the demands of the low-cost sector have seen advances in slimline seating pushed through, such as the popular 9kg (20lb) SL3510 seat from Recaro, fewer efforts to really slim down business class seating have come about. That is, until now.

Veterans of the luxury hospitality and transportation design industry JPA Design are developing the business class seat of the future, set to redefine the premium cabin as we know it. Working in partnership with Williams Advanced Engineering and SWS Certification, they strive to bring the expertise of lightweight construction from the Formula One industry into the aircraft, for the benefit of all.

Stay informed: Sign up for our daily aviation news digest.

Monocoque, lightweight construction and improved PaxEx

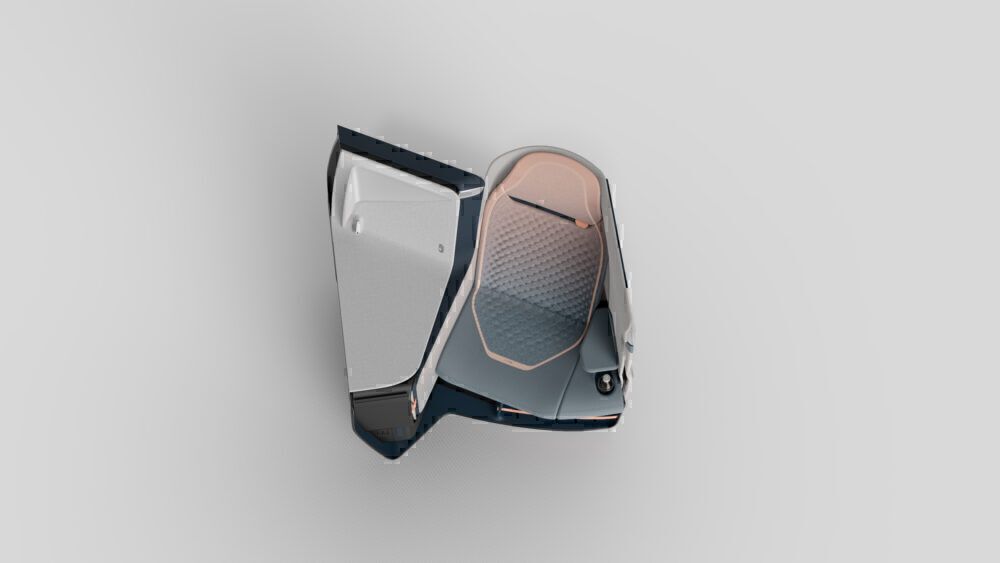

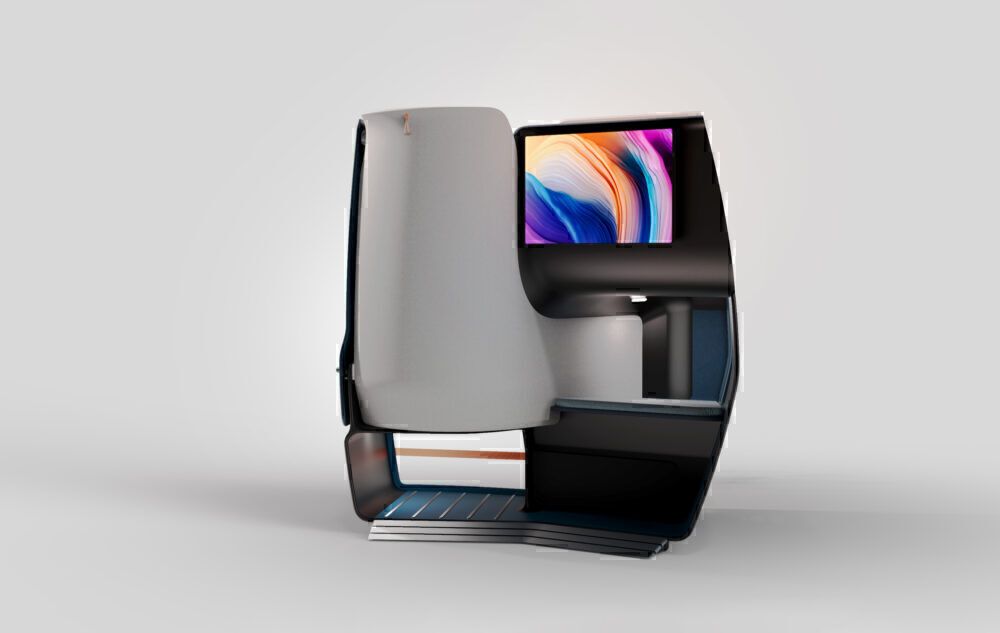

The essence of AIRTEK is in its monocoque, composite construction, something that has been employed by motorsport firms since the 1990s. The structure is self-supporting, with the shell of the seat giving rigidity to the design. This means fewer internal structures are required, leading to a lighter, slimmer aircraft seat.

Because there is something of a unified structure to the seat, it’s less bulky and has fewer moving parts. For passengers, this means more living space per position, and plenty of room to store bags and other belongings. For airlines, it means a lighter seat for less fuel burn and CO2 emissions, as well as a more reliable seat with lower potential for things to go wrong.

It’s not the first time monocoque structures have been used in aviation. JPA Design holds that patent for monocoque structures in aircraft interiors, and leveraged its use in the design of Singapore Airlines’ business class cabin on its Airbus A380s.

Interestingly, the AIRTEK also meets the modern demand for a more hygienic aircraft seat. The team built in COVID safety from the start, developing surface profiles and finishes that promote vertical airflow and circulation onboard. The use of composite materials and reduction in dirt traps naturally leads to a product that is more hygienic and easier to sanitize.

What difference will AIRTEK make?

In terms of weight saving, AIRTEK is aiming to undercut the competition by around 9%. The average A350-900 business class seat weighs around 100 kg (220 lbs), and the AIRTEK aims to deliver a final product weighing just 91 kg (200 lbs). A 20 lb saving might not sound like much, but across a full cabin of 38 seats, it begins to add up. Taking the 760 lbs saved per aircraft and expanding that to an entire fleet could see airlines saving hundreds of thousands of dollars a year.

But it’s not all about benefits to the airline, because passengers are going to love the seat too. The reduced structure of the seat means a full sized cabin bag can be stowed underneath. Less real estate is taken up by the seats themselves, giving the cabin a more open and spacious feel.

To ensure the project doesn’t stumble at any regulatory hurdles, the team includes SWS Certification Services who are building in certification requirements from the start. This should ensure a shorter time to launch and a smoother process of getting the product certified to fly.

UK government funded

The AIRTEK project is one of a number of UK government-funded projects being delivered through the Aerospace Technology Institute (ATI). In total, Westminster is providing grants of £200 million, match-funded by the industry, to help aviation go greener.

As well as AIRTEK, the grant funding has been awarded to a number of other interesting projects. These include Airbus at Broughton in Wales and Filton in Bristol, to design and test wing innovations, the Rolls-Royce UltraFan engine project, and the AEPEC project led by Safran to make energy use on board more efficient.

JPA Design says that more details on the AIRTEK program will be revealed later this year and plan to have a fully resolved model that they will showcase in a digital reveal ready for this year’s Aircraft Interiors Expo, be that an in-person or virtual event.

What do you think of the AIRTEK seat concept? Let us know in the comments.