Summary

- The Boeing 737 aircraft is assembled in several stages, with the fuselage being built by Spirit Aerosystems in Kansas.

- The wings are machined in Washington and assembled with winglets built in the UK and South Carolina.

- The landing gear, tail, engines, and interior are added in various stages, followed by painting and factory check flights.

The Boeing 737 is the manufacturer's best-selling narrowbody aircraft for decades. The company began with the first 737 in the late 1960s, followed by newer variants and next-generation models over the period of several decades. The most recent version of the type, the 737 MAX, is one of the most popular and fuel-efficient aircraft in commercial aviation.

While the type has seen a fair share of downside, Boeing has thousands of orders to be filled for the 737 MAX alone. Have you ever wondered how a Boeing 737 comes together in a factory? Simple Flying delves deeper into the process of assembling the 737 aircraft at the Boeing factory.

First, the fuselage

The fuselage is where the humans fly and sit, the cargo is inserted, and some fuel is kept. The fuselage is also what the wings and tail attach to, and then the engines get connected to the branch, which also has its fuel tanks. It's like the keel of a ship, so where does a fuselage of aluminum alloys come from?

Try Spirit Aerosystems of Wichita, Kansas, which arose from Boeing’s former Wichita campus, a location rich in aviation history initially created by Stearman Aviation in the 1920s. This campus has also worked for Boeing on various aviation projects like Stearman trainers, B-29 Superfortress and B-52 Stratofortress bombers, re-engining KC-135 Stratotankers built initially in Renton, and modifying two 747-200s to VC-25 "Air Force One" standards.

Now Spirit Aerosystems makes fuselages, pylosn, wing leading edges, thrust reversers, and engine nacelles for Boeing 737s. These are then put on trains to send to final assembly in Renton, Washington. Spirit Aerosystems also makes parts for a long list of other commercial aircraft, and is now branching out into military aviation projects.

Once the fuselage arrives in Renton, it's placed on the 737 assembly line to get almost all the flooring. Subsystems like electrical, hydraulic, plumbing, and insulation blankets are installed. Then the doors and radome are attached. This takes the first three days of time on the assembly line.

Now for the wings

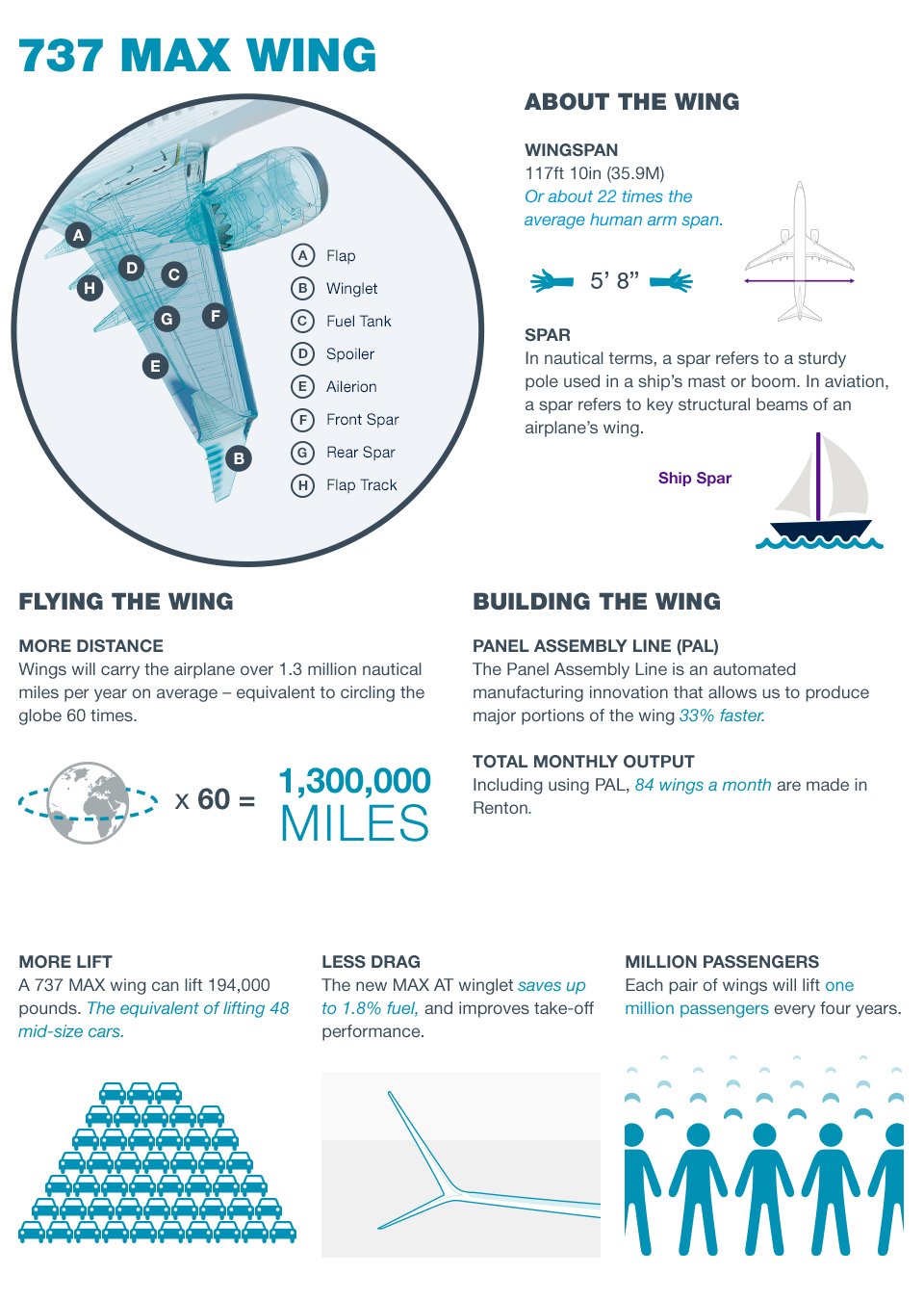

No fuselage can fly without wings, so where do the wings come from? The skins and stringers are machined by Boeing Fabrication Skin and Spar in Auburn and Fredrickson, Washington. The wings are then assembled and attached at the same Renton, Washington campus with 737 Final Assembly, complete with highly engineered winglets meant to smooth airflow over the wing for fuel efficiency.

The 737 MAX split winglets one sees at the end of the airplane wing are built by GKN on the Isle of Wight, United Kingdom with the winglets completed at GKN's facility in Orangeburg, South Carolina. Once the fuselage is ready three days into the assembly, the wings are craned into place and aligned via lasers. Yet, there's still more assembly ahead.

Attaching the landing gear

Of course, no fuselage can take off without landing gear to roll from the gate to the taxiway to the runway and rise. Therefore, each Boeing 737 assembled has landing gear.

Even though the 737 has landing gear that is somewhat exposed in flight, the 737's low landing gear height translates directly into the speed of an aircraft turnaround and ease of maintenance access. This is best shown by the photograph above of a Boeing 737-900ER being turned around and fast unloading and refueling at the Seattle-Tacoma International Airport gate.

The less time necessary to unload baggage from the inbound flight, load baggage for the outbound flight, and refuel plus restock the aircraft equals more schedule reliability, more flights for the aircraft, and more income for the airline. Plus, the 737's landing gear being low means the ability to access more airports, as smaller airports may lack specialized equipment to turn around an airliner.

Connecting the tail and elevator

Wings and a fuselage do not work without a tail unless the airplane is like the B-2 Spirit - a flying wing. The Boeing 737 is not a flying wing, so for stability in the air, the 737 needs a tail. Boeing has outsourced the tailpieces, with the horizontal bottom being made by Korea Aerospace Industries. In contrast, the moving control surface on the flat tail - the elevator - is made by Fuji of Japan.

So the tail is connected on day 5 of assembly. Then plumbing, tubes and ducts, and flight controls are added to make the tail and elevators functional. Functional testing begins to ensure the subsystems are working as they're designed.

Assembling the engine and interior

Good question, especially now that the flight controls are ready to go on days six and seven of assembling this 737. The 737's engines are made by CFM International - a GE-Safran Aircraft Engines partnership with the engines made in Evandale, Ohio, and Villaroche, France. The partnership is headquartered in Cincinnati, Ohio. Once the engines are assembled, the engines are shipped to Renton, Washington, for testing and attachment on the Boeing 737 airframes.

Also, at this time, the 737 interiors are worked on some more. Sidewalls, seats, lavatories, and galleys are installed along the assembly line at this stop.

Now assembled, time for paint?

As you can see above, jetliners that come out of the factory are still covered in their primer. That sight at the end of nine days of 737 assemblies is not what is at the gates of the world's airports.

So how do Boeing 737s get to look ready for revenue service? Naturally, the 737s are taken to a paint shop to get painted. The windows and other sensitive areas are covered. Only then is the primer chemically removed so that the base colors can be painted on. Then stencils and, when necessary, decals are used to finish each airline's desired livery to let the world know whether at an airport or looking up, "This 737 is Airline X's!" The task can take up to 3 days on a 737.

FAA: No Specific Timetable To Certify Boeing 737 MAX 7

In the most recent of a series of setbacks, the FAA has said that it has no timetable to certify the 737 MAX 7.In some photos, you may also notice that the rudder is pre-painted. The rudder is a delicate and essential flight control; it's better to paint the rudder before final assembly. However, Boeing is transitioning towards having the tail 3-D painted to save time and money.

Time to test the 737

Now that the 737 is finally assembled with so many unique parts and painted to look like an airliner, both Boeing and the airline need factory check flights to ensure each aircraft built is fully assembled and functional before paying passengers can safely fly aboard.

After a quick ferry flight from Renton Regional Airport, these check flights are conducted out of Boeing Field (KBFI) in Seattle, Washington. One can watch for such a check flight from Boeing Field's the Museum of Flight's east-facing cafe with both indoor & outdoor seating.

Delivery

Photo: Alaska Airlines

Finally, time to deliver the 737 airplanes to the final customer. The first delivery of aircraft is usually a ceremony with paperwork signing, red carpets, and photo ops. It is a time for Boeing and its subcontractors to celebrate a job well done and for the airline to celebrate the new possibilities that come with a new aircraft in its fleet.

Seem complicated or straightforward? Inspire you to build a model 737? Let us know in the comments below, please.