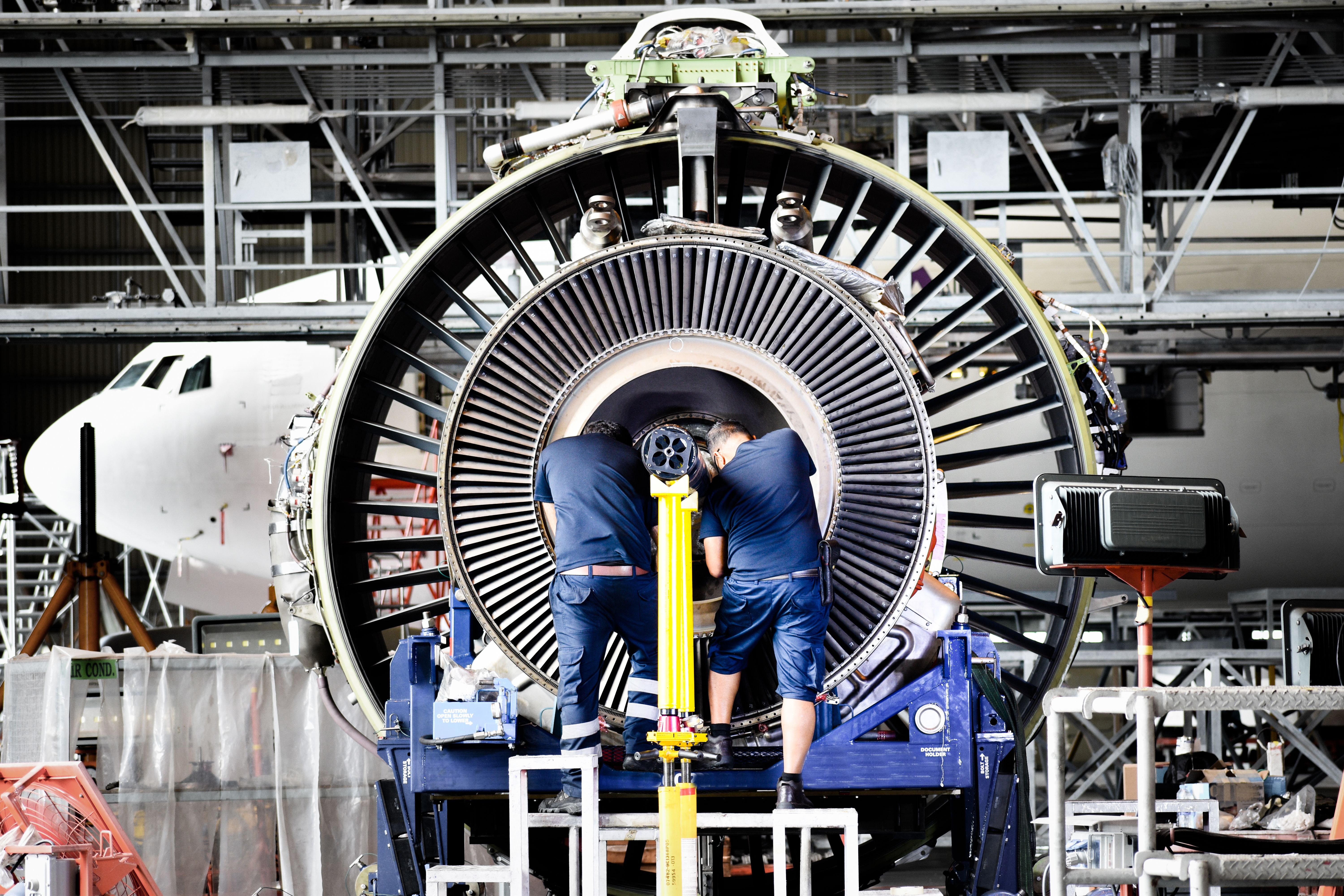

Aircraft MRO (maintenance, repair and overhaul) is an essential element of the global aviation industry. This is where aircraft are inspected, repaired, rebuilt, and refreshed. It’s also where engines are serviced, checked, and have critical parts replaced.

According to Grand View Research, the MRO market was valued at $79 billion in 2022 and is projected to grow at a rate of 5% through 2030, to reach a revenue forecast of $119 billion. The biggest share of this will be in engine overhaul, with significant growth in this market expected as the global aircraft fleet continues to expand.

Despite being a healthy and growing industry, external pressures mean MRO companies must work hard to keep a lid on their costs. Inflation, supply chain constraints and increasing scarcity of raw materials mean it’s never been more critical for MRO providers to be as efficient as possible.

At the same time, there is increasing pressure to maintain a safe working environment for employees. Accidents and injuries are not only bad press for companies; they can also result in sizable compensation claims and labor disputes with the workforce.

Making MRO safer and more efficient

Ensuring safe and highly efficient operations is not always easy for the MRO sector. Simple things like not being able to find the right tool at the right time result in wasted time, as mechanics search around for the item they need. Foreign object debris (FOD) is an ongoing issue, where tools, waste, and other junk is left inside airframes. This leads to customer dissatisfaction and, at worst, can be the cause of costly repairs.

Other challenges come in the form of trying to make a big, busy facility with lots of heavy machinery a safe working environment. Parts supply has become more of an issue in recent months, as the supply chain struggles to restart from the pandemic and parts for older or rarer aircraft become hard to find.

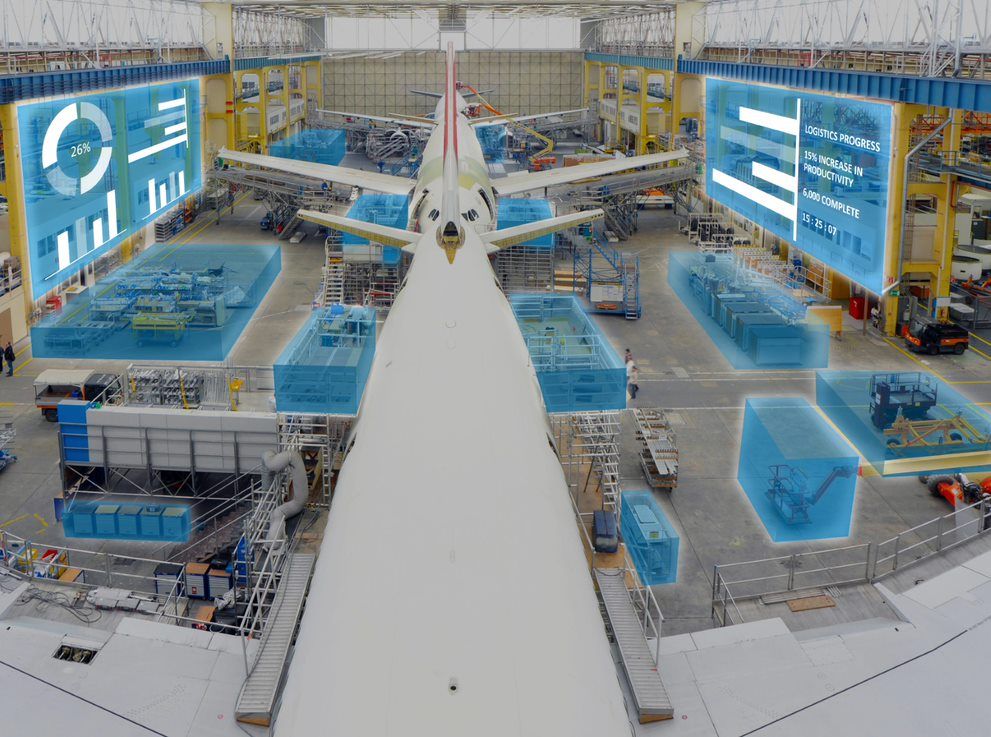

Solving these problems is not easy, but could become a lot simpler in the future with the introduction of ‘smart hangars.’ One company specializing in this technology is UK-based Ubisense; we caught up with their Chief Marketing Officer, Steven Manifold, to find out more about this interesting technology.

What do smart hangars do?

Ubisense has brought to the industry a product it calls SmartSpace - a real-time location solution (RTLS) that tracks and locates assets and people in complex environments. By combining real-time location data with analytics and visualization tools, MRO companies will get valuable insights to help improve operations and increase their efficiency. Steven Manifold commented,

“Smart hangers equipped with RTLS can help solve many of the specific problems that MRO operations face. For example, Smart hangers equipped with RTLS can help MRO operations locate tools quickly and efficiently. Each tool is equipped with a small tracking device that allows the RTLS system to locate it in real-time. This reduces the amount of time mechanics spend searching for tools, leading to increased productivity and decreased downtime.”

This tracking of tools and equipment is essential for eliminating FOD as well. Missing items or items in the wrong place will trigger an alert, preventing items from being left behind in engines and aircraft. And it’s not just tools that can be tracked, as Manifold explained,

“The system can track the movement of workers, ensuring that they are following safety protocols and avoiding dangerous areas. Additionally, the system can be programmed to alert workers if they are entering a dangerous area, helping to prevent accidents and injuries.”

Overall, an RTLS like SmartSpace can help an MRO business to get a better overview o its entire operation. With these insights, managers can rapidly identify where inefficiencies and health and safety hazards are occurring, and put in motion solutions to resolve the problem.

See more stories on aviation MRO here

The future of MRO

Ubisense has already deployed its SmarSpace system at some big-name aviation firms. Safran, the engine maker, and SAEI (Saudia Aerospace Engineering Industries) are both already using the system, but the market is growing and, in the future, we can expect to see many more smart hangars being adopted in the industry.

“Aerospace is a growing sector for Ubisense and SmartSpace, and we are excited to be working with some forward-thinking organizations who believe in the power of RTLS. As more companies see the benefit of adopting these IIoT solutions, we expect to see RTLS proliferate in the aerospace industry.”

With the help of companies like Ubisense, MRO providers can become more efficient, better optimized, and safer places to work. This will help them keep their costs lower - a significant benefit for airlines - and tighten their turnaround times.

Have you heard of smart hangars before? Let us know your thoughts in the comments.

Sources: Grand View Research