Summary

- Different aviation fuel types include Jet A, Jet A-1, Jet B, TS-1, JP-8, JP-4, and AVGAS, each catering to specific needs.

- Geographical differences shape aviation fuel standards, with various regions having specific requirements and fuel grades.

- Emerging aviation fuels like biofuels and alternatives pose challenges despite offering lower emissions.

A deeper examination of aviation fuel composition reveals a complex amalgamation of hydrocarbons and additives meticulously engineered to meet stringent performance and safety standards. A diverse array of hydrocarbons derived from refining crude oil are at the heart of aviation fuel.

Fuel, with its varying prices, affects airline costs and profits every quarter. But what exactly is this fuel made out of? What are the different types of aviation fuel? Here's a quick guide.

Aviation fuel types

What differentiates aviation fuel is the presence of several additives to ensure the fuel can be used safely without crystallization or ignition. These additives ensure the fuel does not freeze at a high temperature or ignite uncontrollably within the fuel chambers.

The two most common types of jet fuel are Jet A and Jet A-1. However, there are other grades of jet fuel available as well:

- Jet A-1 is a type of kerosene-grade fuel commonly used in turbine-engined aircraft, with specific standards including a flash point minimum of 38 degrees Celsius and a freeze point maximum of -47 degrees Celsius, and it's readily available internationally.

- Jet A, similar to Jet A-1 but with a higher freeze point maximum, is primarily found in the USA.

- Jet B, covering naphtha and kerosene fractions, is less common due to its higher flammability but is used in frigid climates. Jet B comprises 30% kerosene and 70% gasoline. However, this fuel type is highly flammable and challenging to handle, with most operators eschewing its use except for military or specific commercial missions. However, Jet B remains available in climates where the risk of fuel freezing is very high, such as northern Canada or Alaska.

How Jet Fuel Is Routed Within Aircraft Engines

Jet fuel passes through various subsystems before being ignited for combustion.- TS-1, prevalent in Russia and the Commonwealth of Independent States (CIS) (formed following the dissolution of the Soviet Union), has slightly different specifications with higher volatility and lower freeze points than Jet A-1.

- Aviation gasoline (AVGAS) is primarily used in older sports and small private aircraft piston engines due to its high octane number. However, its high cost and complexity of engine modifications have led to a shift towards diesel fuel and kerosene.

- JP-8, a kerosene-based fuel, is projected to remain in use at least until 2025. It was first introduced at NATO bases in 1978.

- JP-4 or NATO F-40. JP-4 used to be the primary jet fuel for the USAF but was phased out in the 1990s because of safety problems. A few air forces worldwide still use it, but there is little production.

|

Description |

Jet A-1 |

Jet A |

Jet B |

TS-1 |

|---|---|---|---|---|

|

Fuel Type |

Kerosene-type fuel |

Kerosene-type fuel |

Kerosene-gasoline mixture |

Kerosene-type fuel |

|

Flash point |

38°C |

38°C |

-18°C |

28°C |

|

Freezing Point |

–47.0 °C |

–40 °C |

–60 °C |

–50 °C |

|

Density |

775–840 kg/m3 @ 15°C |

775–840 kg/m3 @ 15°C |

750–801 kg/m3 @ 15°C |

774 kg/m3 @ 20°C |

|

Application |

Civil and military aviation (jet engine, turboprop) |

Civil and military aviation (jet engine, turboprop) |

Civil and military aviation (jet engine) |

Primarily used by military aircraft, including fighter jets, transport planes, and helicopters. It can also be used by some commercial aircraft, although this is less common. |

The difference between Jet A and A-1 is minimal, with the former having a higher freezing point (-40 °C vs -47 °C) and the latter having an additional anti-static additive to the fuel. Their flash point and energy density are almost identical, so both can be used interchangeably on commercial jet aircraft.

|

Description |

JP-4 |

JP-8 |

AVGAS |

|---|---|---|---|

|

Fuel Type |

Kerosene-type fuel like the Jet B, but with the addition of corrosion and icing inhibitors |

Kerosene-type fuel like the Jet A-1, but with the addition of corrosion inhibitors and anti-ice additives |

Gasoline |

|

Flash point |

−18 °C |

38°C |

−43°C |

|

Freezing Point |

−60 °C |

-47°C |

−60 °C |

|

Density |

751 kg/m3 @ 15 °C |

775-840 kg/m3 @ 15 °C |

690 kg/m3 @ 15 °C |

|

Application |

Military jet aircraft |

Military jet aircraft |

Piston-engine powered aircraft |

Geographical differences

According to Shell, in the US, civil jet fuels adhere to ASTM Specification for Aviation Turbine Fuels D 1655, which outlines three grades: Jet A, Jet A-1, and Jet B. Jet B, a wide-cut fuel, is scarcely found except in some areas of northern Canada where its lower freeze point and higher volatility are beneficial for cold conditions and starting. Domestic and international airlines primarily use Jet A within the US.

The UK standard jet fuel, previously known as D. Eng RD 2494, now renamed DEF STAN 91-91, was initially developed for military use but became the standard civil jet fuel in the UK. It specifies requirements for a kerosene-type fuel (Jet A-1 grade). DEF STAN 91-91 closely resembles Jet A-1, defined by ASTM D 1655, with a few stricter requirements.

Jet fuels in the former Soviet Union and Eastern Europe vary in grades, reflecting different crude sources and processing treatments. Soviet fuels, designated as T-1 to T-8, TS-1, or RT, are governed by State Standard (GOST) or Technical Condition (TU) numbers. Soviet fuels typically have a low freeze point but also a low flash point. The TS-1 is comparable to the Western Jet A-1 and is approved by most aircraft manufacturers.

Eastern European countries have their own standards, some resembling those of Russia, while others align more closely with Western Jet A-1 properties and test methods to meet international airline requirements.

Chinese jet fuels are categorized into five types according to current specifications. Previously labeled with the prefix "RP," they are now named No 1 Jet Fuel, No 2 Jet Fuel, and so forth:

- RP-1 and RP-2 resemble Soviet TS-1 kerosene, characterized by a low flash point. RP-1 has a freeze point of -60 degrees C, while RP-2 is -50 degrees C.

- RP-3 mirrors Western Jet A-1 and is mainly produced for export. Currently, most jet fuel produced in China falls under RP-3, now renamed No 3 Jet Fuel.

- RP-4 is akin to Western Jet B and Soviet T-2, a wide-cut fuel.

- RP-5, a high flash point kerosene, is comparable to that used in naval aircraft on aircraft carriers in the West.

Is Aviation Fuel Taxed? If Not, Why Not?

Depending on where in the world a jet is fueling up, the answer can vary wildly.Airport Fuel Dispensing

Airplanes are refueled after pilots assess the fuel needed for the next journey. They communicate the required fuel weight to ground handling and refueling staff, who convert it to volume and fill the tanks accordingly. This information is recorded on a 'refuel sheet' and handed to the fueling company.

Any differences between the requested and actual fuel amounts are noted on the sheet for accurate record-keeping. But how is the fuel loaded into the aircraft? After fuel is stored at an airport, it's distributed to aircraft via three methods:

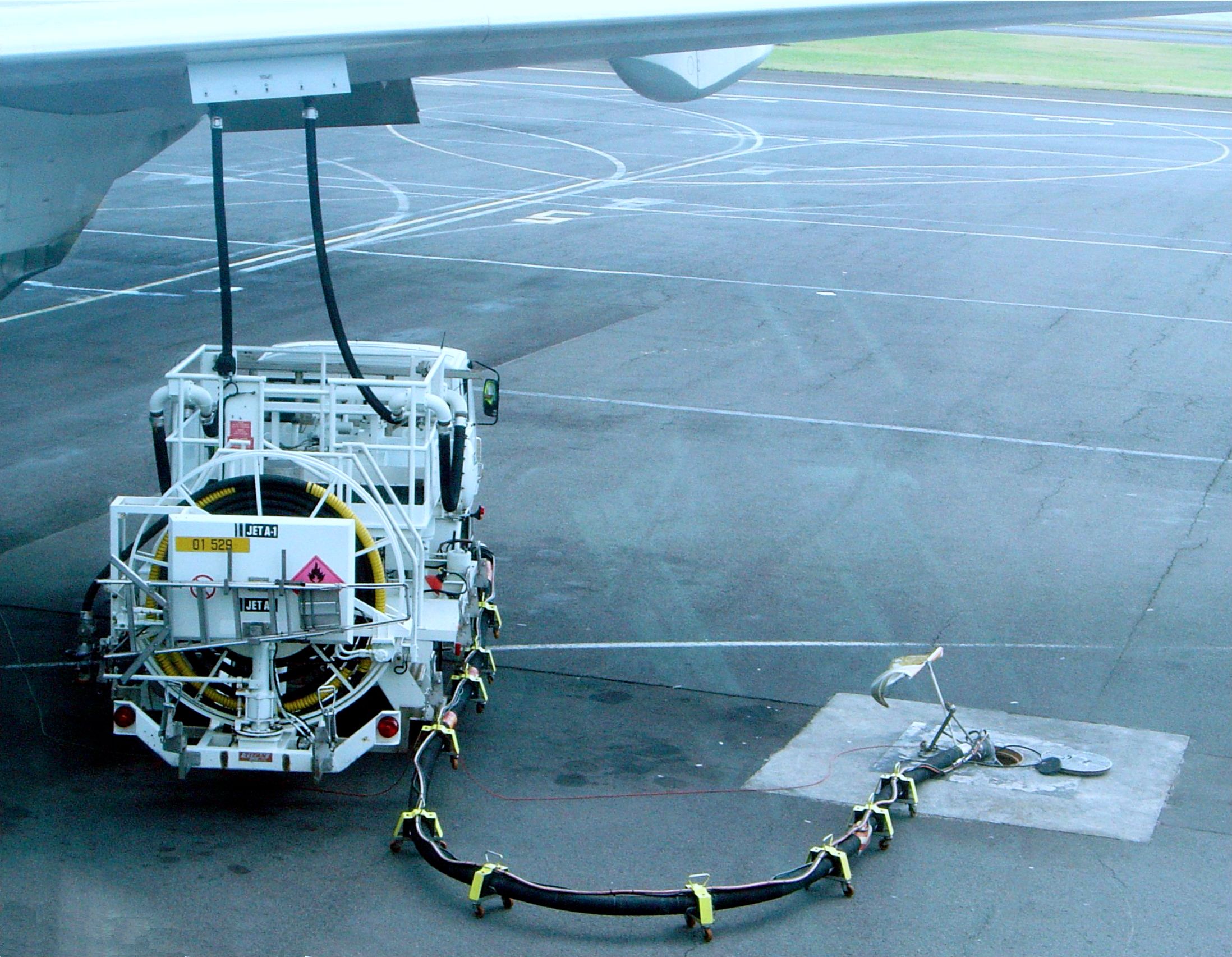

- Hydrant system (for jet fuel). Hydrant systems are prevalent in large commercial airports, with underground pipes linking storage tanks to each gate. A hydrant unit, either a truck or cart, equipped with filtration and volume metering, is used to fuel aircraft. Hydrant trucks have filters or water-absorbing media to prevent contamination.

- Refueler truck (for Avgas or jet fuel). Refueler trucks or dispensers with pumping, filtration, and metering equipment are used at smaller airports.

- Dispenser (for Avgas or jet fuel). Dispensers are similar to gas pumps for cars but tailored for aircraft.

Emerging aviation fuels

The aviation industry is exploring alternatives to conventional fossil fuels, including biofuels like sustainable aviation fuel and straight vegetable oils. These fuels offer lower emissions of particles and greenhouse gases, with minimal modifications needed to aircraft.

However, they face challenges such as higher costs compared to traditional fuels, hindering widespread adoption. Other potential alternatives include compressed natural gas (CNG), liquefied natural gas (LNG), and liquid hydrogen, which offer reduced carbon emissions but present technical and logistical hurdles.

5 Alternative Fuel Technologies That Could Define Aviation's Race To Net-Zero

Alternative power sources are ideal initiatives for industry-wide decarbonization targets.Despite ongoing development, widespread use of hydrogen-powered aircraft remains distant, with near-term alternatives like aviation biofuel and synthetic fuels (e-jet) being more feasible options. In recent years, the aviation industry has moved from crude oil-based fuel to Sustainable Aviation Fuel (SAF). The most promising advancement has been biofuel, produced from vegetable oils, plant materials, and more.

In the EU, aviation contributed 3.8% of CO2 emissions in 2017, with a forecasted tripling of emissions by 2050. According to the European Alternative Fuels Observatory, the EU aims for a 90% reduction in transport emissions by 2050, with goals including zero-emission aircraft by 2035 and carbon-neutral short flights by 2030. These initiatives align with the EU Green Deal. Alternative aviation fuels are:

- Bio-jet fuels, blended with traditional jet fuel, reduce exhaust toxicity and closely resemble conventional jet fuel properties, aiding adoption in existing engines.

- Electrofuels, produced via water electrolysis with captured carbon or nitrogen, offer options like Fischer-Tropsch kerosene, methane, methanol, hydrogen, ammonia, and n-octane.

- Liquefied methane (LNG) is viable as an aviation fuel derived from biomass or electrofuels, but it faces challenges in infrastructure and tank design due to its cryogenic nature.

- Hydrogen (H2) is considered attractive due to its high energy content and carbon-free combustion, but it's highly flammable and requires specific handling.

- Ammonia (NH3), rich in hydrogen and devoid of carbon, can be blended with hydrogen or methane, offering potential as an aviation fuel in modified engines and fuel cells.

What do you think about the future of aviation fuel? Let us know in the comments.